Down-paper Pillow Packing Machine use separate PID control to temperature, suitable for various packing materials, simple driving system, reliable working. no waste packing film....Read more

VIDEO

Introduction

Automatic down-paper pillow packaging machine is also called horizontal down-paper flow packing machine. It is controlled by touch screen controller with human-machine interface, and is easy to set parameter, works in high speed with high efficiency. It is suitable for all kinds of packaging materials.Application:

Packaging various kinds of regular objects like Food (Snack bar, biscuits, pies, chocolates, ice lolly, bread, instant noodles. moon-cakes, drugs, daily appliances( Soap, sponge, tissue, Card ), industrial parts( handle, bearing, Car parts, washer ),paper boxes, plates, plastic(cutlery, tray) etc.Specification:

| Type | YY-250X | YY-350X | YY-450X | YY-600X | YY-700X |

| Film Width | Max.250mm | Max.350mm | Max.450mm | Max.600mm | MAX.700mm |

| Bag Length | 65-190 or 120-280mm | 65-190 or 120-280mm | 120-450mm | 120-500mm | 120-600mm |

| Bag Width | 30-110mm | 50-160mm | 50-180mm | 100-280mm | 100-330mm |

| Product Height | Max.45MM | Max.65mm | Max.80mm | Max.110mm | MAX.110mm |

| Film roll diameter | MAX.320mm | ||||

| Packing Speed | 40-230bag/min | 40-230bag/min | 40-150bag/min | 20-150bag/min | 20-130bag/min |

| Power |

220V 50/60HZ 2.4KW |

220V 50/60HZ 2.8W |

220V 50/60HZ 2.8KW |

220V 50/60HZ 2.8KW |

220V 50/60HZ 2.8KW |

| Machine Size | 3920X670X1320mm | 4020X720X1320mm | 4020X820X1320mm | 4020X820X1320mm | 4020X820X1320mm |

| Machine Quality | 500KG | 550KG | 650KG | 680KG | 720kg |

Features:

1. The pillow bag packing machines adopts photoelectric tracing technology and digital input to ensure accurate sealing & cutting position.2. Self alarm display the malfunction.

3. Constant temperature control and intelligent control on the flow packing machinery.

4. Adopt dual frequency conversion controller, the length of bag can be set and cut at any time without the need to adjust trail operation. It is time saving and film saving.

5. The pillow packaging machine can set the machine stopping position, no sticking to the knife and no film wasted.

Main function:

1. Double transducer control, flexible bag length cutting, operator needn’t to adjust the unloading working, saving time and saving films.2. Human-machine operation, convenient and quick parameter setting.

3. Self diagnosis failure function, clear failure display.

4. High sensitivity optical electric color mark tracking digital input cut position which makes the sealing and cutting more accurate.

5. Separate PID control to temperature, suitable for various packing materials.

6. Stopping the machine in selected position, no sticking to the knife and no waste packing film.

7. Simple driving system, reliable working, convenient maintenance.

8. All the controls on the down-paper pillow package machinery are achieved by software, convenient for function adjusting and upgrading.

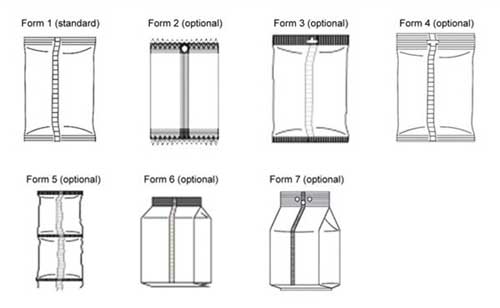

Bag type:

Optional accessories

1: Date Coder2: Touchable Screen

3: Automatic Punching Device

4: Alternative sealing patterns and notch

5: Auto labeling device

6: Deoxidizer chute device

7: Gas flushing device

8: Alcohol spraying device 9: Auto feeder