Rotary pillow packing machine use high sensitivity photoelectric eye color trace the bag, all control is realized through software, easy for operate and technical upgrade....Read more

VIDEO

Introduction

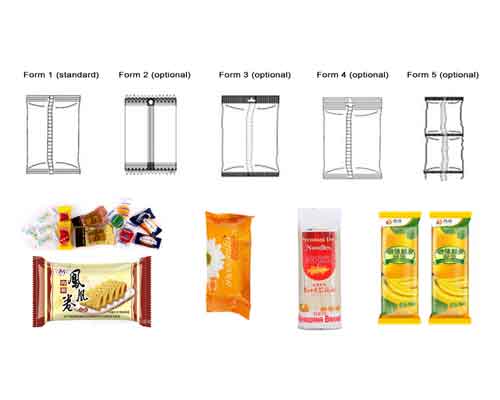

This automatic rotary pillow packing machine is also called horizontal rotary flow packing machine. It is specially designed for packing all kinds of special shaped articles. It adopts PLC program control, photo-electricity paper mould adjustment, electronic text display, four groups of auto thermo regulators, and frequency conversion speed regulation for main motor. These devices are advanced in techniques and easy to handle. This pillow bag packing machine characters good airtight, clear sealing, tidy and sanitation, legible and fast, stable running, low noise and high efficiency.Application:

Horizontal flow packing machines suitable for packaging various kinds of regular objects like:• Food : like Biscuits , Pies , Chocolates , Bread , Instant noodles, Cup Cakes ,Energy bar ,Ice cream bar,etc ...

• Daily Appliances : Soap bar ,Sponge, Tissue etc ...

• Medical Product: Medical marks, gauze, abrasive, drugs, blood sampling device, etc...

• Stationery: ball pen, color pen, mark pen, Transparent adhesive, rulers, books, paper cards, etc...

• Different kinds of Hardware and decoration products.

Features:

1.Efficient: Bag - making, filling, sealing, cutting, heating, date / lot number achieved in one time.2. Intelligent: Packing speed of pillow bag package machine and bag length can be set through the screen without part changes.

3. Profession: Independent temperature controller with heat balance enables different packing materials.

4. Characteristic: Automatic stop function, with safe operation and saving the film.

5. Convenient: Low loss, labor saving, easy for operation and maintenance.

6. Photoelectric tracing for paper cutting, new structure, easy and simple operation etc.

Main performance and structural characteristics:

1. Dual inverter control on the pillow packing machinery, bag length can be setting and cutting, without air conditioning go.2. Man-machine interface, convenient parameter setting.

3. Self-diagnostics, fault can been seen at a glance.

4. High sensitivity photoelectric eye color tracing, digital input cut position which makes the cutting position more accurate.

5. Temperature independent PID control, and better suited to a variety of packaging materials.

6. Positioned stop function, without sticking knife or wasting film.

7. Powertrain simple, it reliable, more convenient maintenance software implementation of all control posts to facilitate the function of restructuring and technological upgrading, never backward.

Specifications:

| Model | Film width | Bag length | Bag width | Product height | Film roll diameter | Packing speed | Power | Dimension | Weight |

| YY-250B | Max.250mm | 65-190 or 120-280mm | 30-110mm | Max.40mm | Max.320mm | 15-230bags/min | 220v 50/60Hz 2.4kw | 4090*680*1420mm | 500kg |

| YY-250D | 90-220mm | Max.55mm | |||||||

| YY-250E | Max.180mm | 50-115mm | 30-80mm | Max.35mm | 60-330bags/min | ||||

| YY-250S | 45-90mm | ||||||||

| YY-320B | Max.320mm | 65-190 or 120-280mm | 50-160mm | Max.40mm | 15-230bags/min | 220v 50/60Hz 2.6kw | 4090*720*1420mm | 550kg | |

| YY-320D | 90-220 or 150-330mm | Max.55mm | |||||||

| YY-350B | Max.350mm | 65-190 or 120-280mm | 50-160mm | Max.40mm | Max.320mm | 15-180bags/min | 220v 50/60 Hz, 2.6kw | 4300*770*1420mm | 580kg |

| YY-350D | 90-220 or 150-330mm | Max.60mm | |||||||

| YY-400 | Max.400mm | 150-400mm | 50-180mm | Max.65mm | 30-150bags/min | 220v 50/60 Hz, 2.8kw | 600kg | ||

| YY-450 | Max.450mm | 130-450mm | Max.75mm | 4300*820*1420mm | 650kg | ||||

| YY-600 | Max.600mm | 120-500mm | 100-280mm | Max.110mm | 20-150bags/min | 4340*970*1500mm | 680kg | ||

| YY-700 | Max.700mm | 120-600mm | 100-330mm | 20-130bags/min | 4380*1070*1500mm | 720kg |

Optional device:

1.Lateral feed device2.Straight feed device

3.Belt material conveyor

4.End sealing auxiliary conveyor

5.Auxiliary material feeding device

6.Material cut prevent device

7.Perforating device

8.Angle folding device

9.Printer

10.Labeling machine