This production line has a high degree of automation, high product quality, and can accommodate production modes such as potato chips and french fries, reducing energy consumption and resource waste, and flexibly responding to market changes...Read more

VIDEO

Introduction

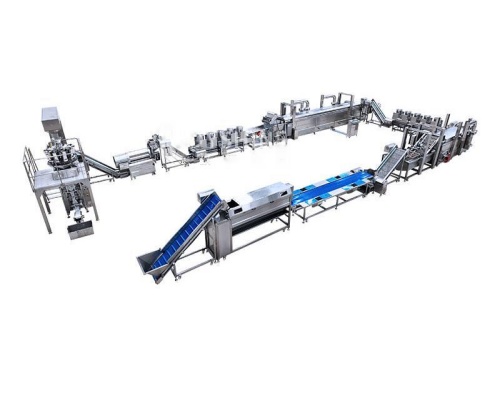

The potato chip processing production line usually includes raw material processing, slicing, cleaning, blanching, cooling, frying, deoiling, seasoning, packaging and other links, which are interconnected through automated equipment to form an efficient and continuous production line.It can meet the needs of large-scale potato chip production enterprises and can be packaged in various forms such as bags and barrels. The production line has high flexibility and can produce different product forms such as potato chips and french fries in one production line

Work Flow:

Cleaning potatoes - peeling potatoes - picking - slicing - cleaning surface starch - blanching - air drying - frying - deoiling and cooling - seasoning - packagingAdvantage:

1. Improve production efficiency:The fully automatic potato chip (french fry) production line achieves continuous and automated production processes through precise design and optimization, reducing manual intervention and operation time.

2. Ensure the quality of potato chips (fries):

The fully automated production line ensures consistency and stability in the food processing process by precisely controlling production parameters such as temperature, pressure, time, etc.

3. Reduce energy and resource consumption:

The fully automatic potato chip (french fries) production line adopts advanced energy-saving technology, which can reduce energy consumption and resource waste. In addition, automated equipment can reduce the generation of waste and by-products, further lowering production costs.

4. Improve food safety and hygiene:

Automated equipment can implement strict cleaning and disinfection procedures during the production process, effectively reducing food safety risks. Through automated cleaning and disinfection systems, the equipment can ensure no dead corners and prevent the growth of microorganisms and harmful substances.

5. Flexibly respond to market changes:

The fully automatic potato chip (french fry) production line has high flexibility and adjustability, and can quickly adapt to changes in market demand. Enterprises can adjust equipment parameters and production processes according to market demand to achieve small batch and multi variety production.

Main equipments:

1.Elevator: To lift and transport fresh potatoes for the next step of washing and peeling.

Application:

Suitable for enterprises such as food processing plants, central kitchens, restaurants and hotels, and snack food processing plants for the production of fruit and vegetable fried foods such as potato chips, French fries, banana slices, etc.