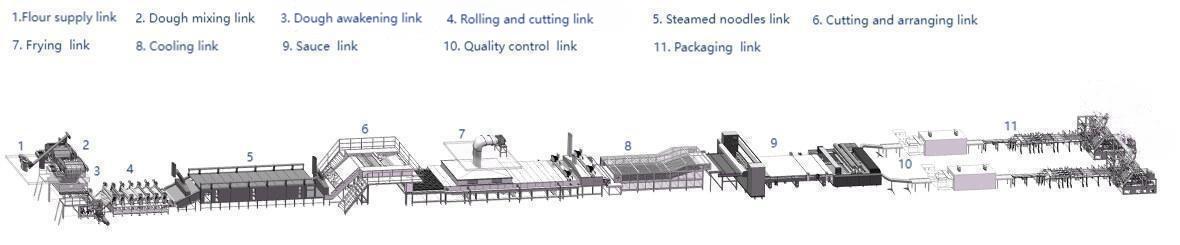

The process of fried instant noodles production line includes Flour supply link, Dough mixing link, Dough awakening link, Rolling and cutting link, Steamed noodles link, Cutting and arranging link, Frying link, Cooling link, Sauce link, Quality contr...Read more

VIDEO

Introduction

The instant noodle production line is divided into fried instant noodle production line and non-fried instant noodle production line.The process of fried instant noodles production line includes Flour supply link, Dough mixing link, Dough awakening link, Rolling and cutting link, Steamed noodles link, Cutting and arranging link, Frying link, Cooling link, Sauce link, Quality control link and Packaging link. The surface blocks can be made in square and round shapes, and the weight is determined by the customer's choice. The whole set of equipment adopts automatic production line, such as automatic cutting, automatic folding, automatic frying box. The production capacity of the whole production line ranges from 88,000 to 1.2 million pieces per day (24 hours).

The only difference between the process of non-fried instant noodles production line and the process of fried noodles production line is that the non-fried noodles line uses steam drying, not frying, so the noodles do not contain oil.

Steamed noodles require steam, so a boiler is needed. The part of the contact surface is made of stainless steel and food grade conveyor belt, and the press roller is alloy cast steel, which is very hard.

Work Flow:

The powder is fed directly by sifting machine and screw conveyor or by centralized automatic feeding. The flour is quickly sent to the flour mixer by positive pressure. Full automatic operation, effectively reduce labor intensity, full monitoring, accurate quantitative, to ensure food safety and reliability. The main equipment is powder feeding machine.

2. Dough mixing link

It is to mix flour and water evenly for a certain time to form a wet dough with certain processing properties. The main equipment is a brine mixing system and a flour mixer.

Basic principle: When flour is evenly mixed with water, the gluten and glutenin in the flour absorb water and expand, surrounded by a network of wet gluten. When a certain gluten network is formed, stop fast beating so as not to interrupt the formed network, and start slow beating to further expand and extend the gluten, so that the dough formed has good processing properties.

3. Dough awakening link

Aging is also called wakes up the dough, a process that further improves the processing properties of the dough with the passage of time. The main equipment is dough aging machine.

4. Rolling and cutting link

The matured dough is continuously rolled by a multi-channel press roller to meet the requirements of a certain thickness of the surface, and then through a pair of knife rollers, is cut into strips, through the molding machine transmitted to the molding mesh belt to form a wave shape, that is, the unique shape of instant noodles. The main equipment is compound press and cutting machine.

5. Steamed noodles link

The noodles are heated and steamed through steam at a certain time and temperature. It's actually a process of starch gelatinization. Gelatinization is a process in which starch particles absorb water and dissolve at the appropriate temperature, forming a paste, and starch molecules change from a regular arrangement to a chaotic arrangement, so that enzyme molecules are easy to enter between molecules and easy to digest and absorb. The main equipment is noodle steaming machine.

6. Cutting and arranging link

Through the quantitative cutting equipment, the corrugated surface strip from the steaming machine is cut off according to a certain length, and the cut surface strip is folded in half to arrange output, and after cutting into the box, it is blown and shaped and then enters the frying stage. You can make different sizes of square or round flatbread. The main equipment is quantitative cutting machine and trimming machine.

7. Frying link

It is to put the quantitative cut noodles into the frying box, through the high-temperature oil tank, the water in the noodles quickly vaporized, the noodles formed porous structure, starch further gelatinization, improve product quality, while conducive to storage. The main equipment is frying machine.

8. Cooling link

Fresh out of the fryer, the pastry temperature is too high, will burn the packaging film and soup, so several sets of fans are often used to cool it to room temperature for packaging. The main equipment is air cooling machine.

9. Sauce link

Mix all kinds of spices according to a certain proportion to make seasoning sauce. The main equipment includes sauce stir-frying machine, powder and vegetable bag mixing and packaging machine, and parcel delivery machine.

10. Quality control link

Products are inspected by weighing and foreign body screening machines to ensure product quality. The main equipment is foreign body screening machine.

11. Packaging link

The fried noodles and sauce are packed into packaging bags, which are sealed/capped by sealing equipment. Finally, the products are packed and boxed by packing equipment. The main equipment is sealing machine, capping machine, packing machine.

Advantage:

1.High degree of automation: This production line adopts system control, which can achieve a fully automated production process from raw materials to finished products, allowing you to reduce labor input.2. High production efficiency: The automation process of the production line significantly improves production efficiency, allowing for large-scale production with minimal manual labor, achieving all-weather operation, reducing downtime, and improving production efficiency.

3. High consistency of product quality: Automated production avoids errors caused by human factors, ensuring consistency in size, shape, and texture of fried instant noodles. Accurate control of ingredients and cooking parameters can ensure consistency in taste and quality, thereby significantly improving product quality consistency.

4. Reduce production costs: Automated assembly lines help you reduce labor costs, minimize human errors, and save total costs while improving efficiency. Effectively utilizing raw materials and energy can help improve the cost-effectiveness of the production process.

5. Improve production safety: Automation reduces labor input, reduces labor intensity of workers, and thus improves production safety.

6. Easy to operate without experience: Personnel do not need experience, simple training is enough to operate.

7. Real time monitoring and data analysis: It has the ability to monitor various parameters and states in the production process in real time, and collect and analyze data through computer systems to timely detect abnormal situations and perform fault diagnosis and prediction, thereby improving the stability and reliability of the production line.

8. Customized services: According to your needs, we can provide the following customized services:

Shape customization:Rectangular, Round

Packaging customization: Cup, barrel, bowl, bag

Capacity customization: 3700pcs/h-50000pcs/h

Application:

Applicable products: bag instant noodles, barrel instant noodles, cup instant noodles, bowl instant noodles.

Specifications:

| Model | Capacity | Power(kw) | Steam consumption |

| 350 | 3700PCS/H | 40 | 0.8-1.0T/H |

| 500 | 5000PCS/H | 55 | 1.2-1.4T/H |

| 750 | 7500PCS/H | 60 | 1.2-1.4T/H |

| 1000 | 10000PCS/H | 75 | 1.6-2.0T/H |

| 1500 | 15000PCS/H | 90 | 2.0-2.4T/H |

| 2000 | 20000PCS/H | 110 | 2.4-2.6T/H |

| 2500 | 25000PCS/H | 115 | 2.8-3.0T/H |

| 3000 | 30000PCS/H | 130 | 3.5-4.0T/H |

| 3500 | 37500PCS/H | 150 | 4.0-4.5T/H |

| 5000 | 50000PCS/H | 200 | 4.5-5.0T/H |