Project Background: Pain Points of Russian Customers in Citrus Processing

As an important citrus consumption market, Russia's local fruit and vegetable processing enterprises face challenges such as low efficiency in manual sorting, high loss rates, and insufficient product standardization. The customer's existing production line equipment is outdated, resulting in incomplete cleaning and uneven air drying, which makes citrus prone to spoilage during storage and transportation, seriously affecting profit margins. The customer urgently needs an automated, high-precision processing line to achieve integrated and efficient processing from cleaning, air drying to grading.Solution: Customized citrus cleaning, drying and sorting processing line

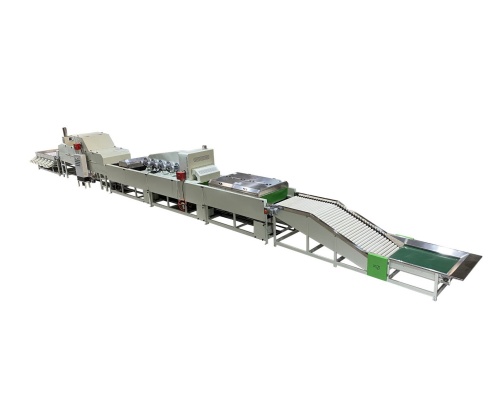

Our technical team has designed a fully automatic citrus cleaning, drying and sorting processing line tailored to the climatic conditions in Russia and export standards. The core modules include:1. Intelligent Cleaning Module

· Utilizes high-pressure spraying and rotating brush technology, with a 304 stainless steel body. It can effectively remove pesticide residues and soil from the surface of citrus fruits, and after cleaning, it achieves deep air drying through a hot air circulation system to prevent uneven waxing in the future.

· Customer Value: The cleaning qualification rate has been increased to 99.5%, reducing the cost of manual secondary screening.

2. Spectral Sorting Module

· Integrates multi-spectral non-destructive detection technology, enabling simultaneous analysis of fruit diameter, sugar content, and defects (such as frost damage and blemished skin) within 0.3 seconds. Supports 24-level precise grading and can be customized with "leaf-on sorting" function to increase product premium value.

· Customer Value: Sorting efficiency reaches 12 tons per hour, export qualification rate has risen from 60% to 95%, meeting EU market access standards.

3. Preservation Processing Module

· Equipped with a food-grade automatic waxing machine, which evenly applies fruit wax using 15 brushes, controlling the wax layer thickness to be ≤ 0.1mm to avoid affecting the fruit's respiration process; combined with UV sterilization technology, the shelf life is extended to 45 days.

· Customer Value: The loss rate is reduced by 12%, and the customer order repeat purchase rate increases by 40%.

4. Intelligent Packaging Module

· Integrates a single fruit bagging machine and an automatic box sealing and packaging line, capable of adapting to the packaging of multiple specifications of films ranging from 160x200mm to 190x230mm. Combined with the blockchain traceability system, it generates a "quality identity card" to enhance brand trust.

· Customer Value: Packaging efficiency is increased by 3 times, and labor costs are reduced by 80%.

Demo video of similar equipment:

Oranges cleaning, drying, waxing and sorting production line

Fruit Washing Waxing, Drying and Sorting Line

Outcomes and Feedback: Efficiency Enhancement and Long-Term Benefits

Production Capacity Breakthrough: The production line can process up to 8-10 tons of citrus fruits per hour, and the daily processing volume has increased by 300%. This perfectly meets the peak demand of customers.Significant Reduction In Loss Rate: Automated sorting reduces manual contact, and the product spoilage rate has dropped from 8% to less than 2%.

Remarkable Energy-saving Benefits: It saves approximately $120,000 in electricity and labor costs for customers each year.

Customer Feedback: "The equipment from Union Machinery has reduced our citrus processing costs by 30%. The products have successfully entered high-end supermarkets in Moscow. Thank you for the customized services provided by the professional team!" —— Production Director of Russian Customer

Why Choose Union Machinery?

Industry Specialization: Over a decade dedicated to the R&D and manufacturing of food packaging machinery, deeply understanding the processing and packaging characteristics of fruits and vegetables.Customization Capability: Can provide personalized solutions based on customers' specific products, packaging dimensions, and production capacity requirements.

International Certification: The equipment complies with international standards such as CE and ISO, and has been exported to 50+ countries and regions worldwide.

Full Cycle Service: Full support from demand analysis, scheme design, installation and commissioning to after-sales training throughout the process.

Cost-Performance Advantage: Compared to similar equipment from Europe, offers the same performance but with more competitive pricing options.

Invite Cooperation

Whether you are from Egypt, the Middle East, or other regions around the world, whether you need coffee capsule packaging machines, liquid filling lines, or complete fruit and vegetable processing solutions, Union Machinery can assist you in achieving production automation upgrades and commercial success with professional technology and sincere service.Contact us now to obtain your customized equipment solution.

Union Machinery, A global leader in food packaging, committed to enhancing customer competitiveness through innovative machinery. Complete export certification and 100% on-time project delivery rate.

Union Machinery —— Make every citrus fruit a quality guarantee!