Fully automatic cleaning, air drying and sorting production line helps increase production capacity by 300%

In September 2023, our company successfully customized and delivered a cherry tomatoes cleaning, drying, and sorting production line for an agricultural product processing enterprise located in Thailand. The customer is mainly engaged in the production and processing of agricultural products. The automated production line purchased this time not only meets their full process needs for cleaning, drying, and sorting of cherry tomatoes, but also significantly improves their production efficiency and profitability.

I. Customer Core Requirements

l Efficiency bottleneck: Traditional manual sorting is slow and cannot meet the demand for rapid increase in orders.

l Quality instability: Manual cleaning may leave pesticide residues, and incomplete drying leads to the risk of mold.

l Cost pressure: Labor shortage raises labor costs, and high energy consumption increases operational burdens.

l Export compliance: It is necessary to meet the hygiene standards and testing requirements of markets such as the EU and the US.

II. Our Company's Solutions and Product Advantages

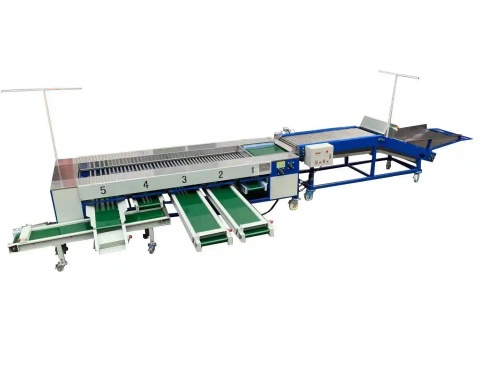

1. Modular intelligent production line

· Cleaning system: Two-stage vortex cleaning + high-pressure spray, pesticide residue removal rate ≥ 99.5%.

· Drying technology: Hot air circulation + centrifugal dehydration, complete skin drying within 1 minute, mold occurrence rate reduced to 0.2%.

· Sorting equipment: AI visual recognition + multi-spectrum detection, simultaneously complete size, color, and defect sorting, accuracy up to ±0.5mm.

2. Energy-saving and Adaptability Design

· Utilizing variable-frequency motors and waste heat recovery systems, energy consumption is reduced by 40%.

· All stainless steel body with IP66 protection level, suitable for the high-temperature and high-humidity environment in Southeast Asia.

· Modular structure supports later capacity expansion, and the investment return period is shortened to 10 months.

III. Implementation Results

· Capacity Enhancement: The daily processing capacity per line has increased from 5 tons to 15 tons, meeting the demand for orders during peak seasons.

· Cost Optimization: Labor costs have decreased by 60%, and energy expenses have dropped by 35%.

· Quality Upgrade: The accuracy rate of classification is as high as 98%, the product consistency is excellent, customer satisfaction has significantly improved, and the export unit price has increased by 20%.

Ⅳ.Why Choose Union Machinery?

· Expert Team: End-to-end engineering support from design to commissioning.

· Global Expertise: 11+ years in food machinery, serving 50+ countries.

· Certifications: ISO9001 and CE compliant.

· Custom Solutions: Full-service support, including plant layout optimization.

· Support: 24/7 technical assistance, spare parts availability, 1-year warranty.

If you face production bottlenecks, high energy costs, or equipment compatibility challenges, reach out to Union Machinery!

· Free production line diagnostics

· Customized solution design

· Capacity simulation & ROI analysis

Union Machinery —— Make every single cherry tomato a quality brand card!