Mobile Container Equipment Solves the Problem of Tons of Bulk Grain Transportation

Late autumn of 2023, a Pakistani agricultural products company faced severe challenges: thousands of tons of bulk grains were piled up at the port every day, the fixed packaging workshops were inefficient, and the expensive demurrage fees kept accumulating. What was even more troublesome was that up to 40% of the country's agricultural products were spoiled and lost due to insufficient packaging efficiency and transportation delays.

At this point, a mobile container-based grain packaging line from China was deployed at the port. Just a few weeks later, the packaging efficiency increased by 40%, and the port congestion crisis was resolved smoothly.

Market Pain Point: When a Loss of Billions of Dollars Collides with an Opportunity for Transformation

The agricultural economy of Pakistan holds a significant position in the national economy. However, the lagging packaging technology leads to astonishing waste - 30% to 40% of fruits and vegetables are lost each year due to insufficient packaging, and the food processing sector suffers a loss of up to 10 billion US dollars. The traditional packaging model has three fatal flaws:

- Efficiency Dilemma: Fixed packaging workshops result in bulk grain needing to be transported by trucks, leading to prolonged stay at the port.

- Cost Black Hole: The import tax system for packaging materials is complex, and the tax refund process erodes the profits of enterprises.

- Equipment Deficiency: The proportion of jute bag packaging is too high, while high-value-added packaging equipment is scarce.

Our solution: A disruptive Innovation of Containerized Packaging Lines

In November 2023, the mobile packaging system we specially designed for our Pakistani clients was successfully delivered. The core advantage of this revolutionary equipment directly addresses the industry's pain points:

- Space Revolution: The entire system is integrated into standard containers, enabling direct access to the port's front-line operations, eliminating the need for grain transfer processes.

- Performance Enhancement: A processing capacity of 1400-1800 bags per hour, with a daily processing volume equivalent to the transportation capacity of 30 trucks.

- Environmental Mastery: The dust-proof and moisture-proof design is suitable for the port's open-air environment, operating stably within the temperature range of -15℃ to 50℃.

"Previously, the bulk grain needed to be transported to a packaging workshop 10 kilometers away. Now, the packaging and loading onto ships are completed directly at the port. The logistics cost has decreased by 25%." — Feedback from the Pakistani customer three months after the project started.

Practical Application: The Reconfiguration of the Port Logistics Chain

The deployment of this equipment at the Port of Karachi has created a new operational paradigm:

Bulk grain ship docking → Unloading grain into temporary silo → Mobile packaging line on-site packaging → Transport the finished products directly

This process perfectly implements the "disperse - collect - distribute" model. After arrival at the port, there is no need to build a fixed packaging workshop. The mobile equipment can immediately form packaging capabilities, achieving:

Ship Detention Reduced by 50%: Packaging efficiency matches unloading speed

Flexible Packaging Specifications: Supports bag sizes ranging from 25 to 100 kg, compatible with PP woven bags.

Multi-port Transfer Operation: The equipment can be towed to different ports for shared use.

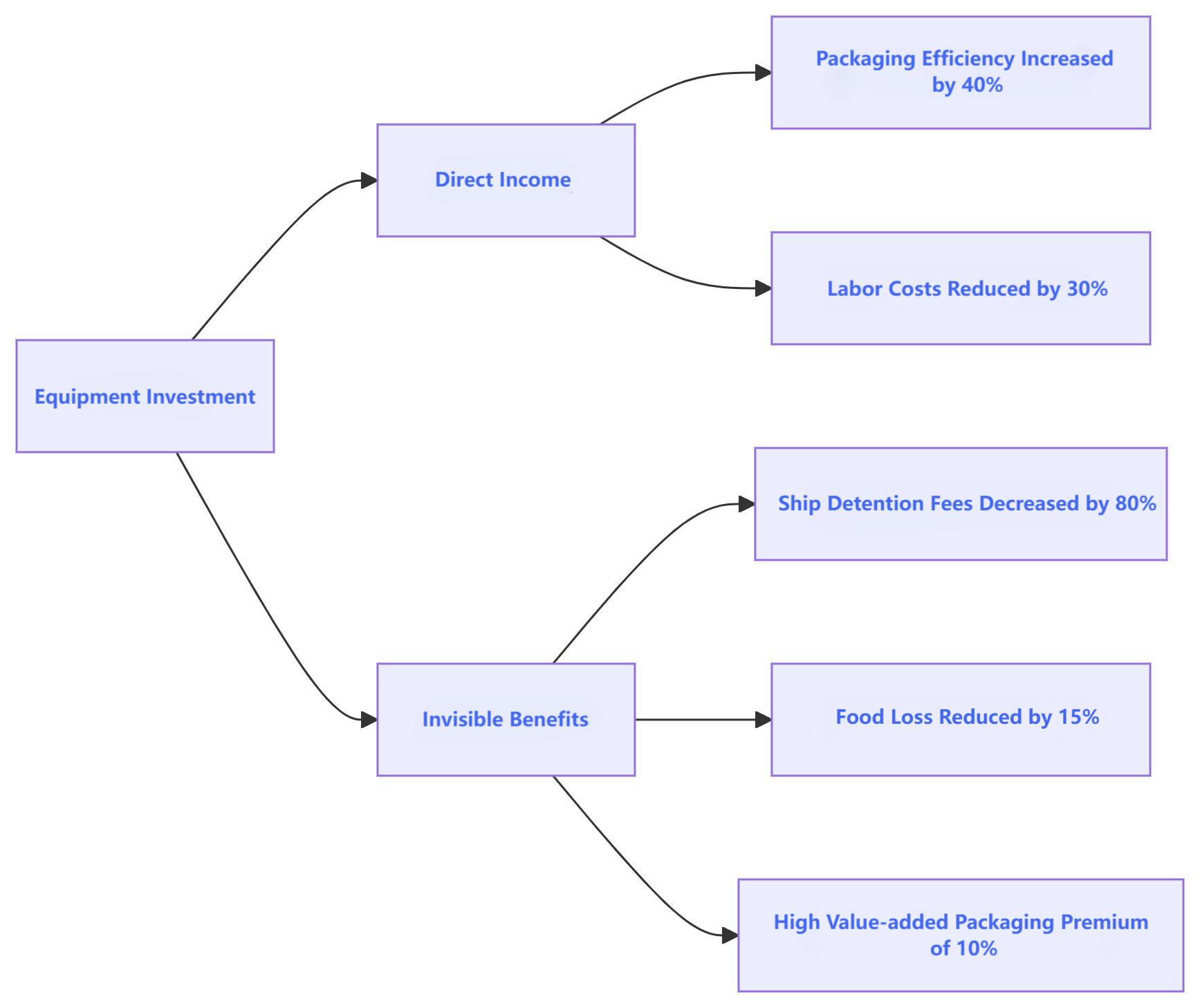

Value Verification: From Cost Center to Profit Engine

The economic accounts for the six-month operation show:

This packaging line has become the "mobile money-printing machine" of the port - processing 600 tons of grain per day. It converts waste into profits and gives Pakistani agricultural exporters the initiative in international logistics timeliness.

By advancing the packaging process to the port, we not only shortened the logistics chain, but also pressed the pause button before the countdown to agricultural product spoilage. This is the true value that Union Machinery equipment brings to global trade - using mobile productivity to break through time and space barriers.

Why Choose Union Machinery?

· Expert Team: End-to-end engineering support from design to commissioning.· Global Expertise: 11+ years in food machinery, serving 50+ countries.

· Certifications: ISO9001 and CE compliant.

· Custom Solutions: Full-service support, including plant layout optimization.

· Support: 24/7 technical assistance, spare parts availability, 1-year warranty.

If you face production bottlenecks, high energy costs, or equipment compatibility challenges, reach out to Union Machinery!

· Free production line diagnostics

· Customized solution design

· Capacity simulation & ROI analysis