【Panama Customer Case】High - efficiency Bubble Cleaning + Intelligent Sorting Equipment Combination

Helps Boost Fruit and Vegetable Processing Efficiency by 200%

Introduction

In July 2023, our company successfully delivered a fully automated bubble cleaning + drum sorting integrated production line to a large - scale fruit and vegetable processing enterprise in Panama. Through customized design and precise technical adaptation, we achieved a two - fold increase in the customer's production capacity and an upgrade in product quality control.I. Customer Pain Points and Requirements

The Panamanian customer is mainly engaged in fruit and vegetable exports and is facing issues such as low efficiency of traditional cleaning and sorting, high labor costs, and a product loss rate exceeding 15%. The requirements include:· Deep - cleaning technology suitable for high - viscosity impurities on the fruit surface.

· Continuous operation capacity with a processing volume of ≥3 tons per hour.

· Automated sorting with a diameter grading accuracy of ±2 mm.

· Rust - proof treatment of equipment to adapt to the tropical humid environment.

II. Highlights of the Solution

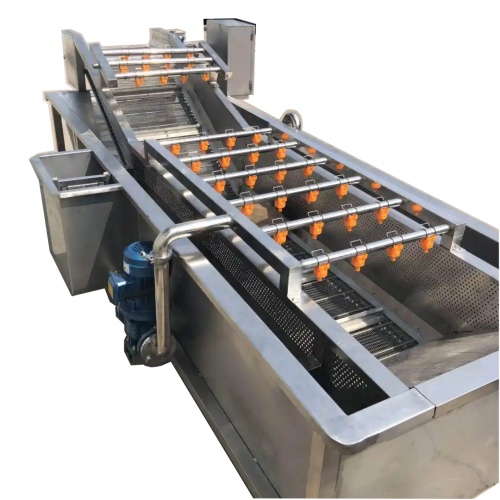

1. Modular Bubble Cleaning System

· It adopts a high - pressure vortex bubble generating device, combined with a three - stage spray design, achieving a 99.2% removal rate of sediment on the fruit and vegetable surface.· It is equipped with a customized 304 stainless - steel thickened box and a food - grade conveyor belt, which has passed the salt - spray test certification to ensure durability in the tropical climate.

2. Intelligent Drum Sorting Module

· It is equipped with multi - stage drum technology to achieve diameter grading of fruits and vegetables (5 adjustable levels), with an accuracy error of ≤2.0mm.· It is equipped with a photoelectric sensing emergency stop system that automatically alarms when foreign objects are mixed in, reducing raw material loss.

3. Turn - key Project Service

· An L-shaped production line is designed according to the layout of the factory building, saving 30% of the floor area.· A detailed operation manual and a remote operation and maintenance system are provided, with a response time of <4 hours.

III. Why Choose Us?

· Industry Accumulation: We have been focusing on food machinery R & D for 11 years and have served customers in more than 50 countries worldwide.· Technical Support: We offer on - site installation and debugging, on - site training, and online guidance.

· Customization Capability: We support the expansion of the production line (such as adding ultrasonic cleaning, air - drying, waxing, packaging and other modules) to meet the certification requirements of multiple countries such as FDA/CE.

· Overseas Experience: We have a professional technical team that can provide full - process escort from customs clearance to installation.

Get Your Exclusive Solution Now

☎️ Call +86 - 135 - 23318588 to get the "Selection Manual for Tropical Fruit Processing Equipment" for free.�� Or visit www.hnunmachinery.com/case/ to view successful cases in more than 20 countries.

➡️ Or click the link www.hnunmachinery.com/Fruits-and-Vegetable-Washing-Machine/ www.hnunmachinery.com/Fruits-and-Vegetable-Sorting-Machine/ www.hnunmachinery.com/Fruit-and-Vegetable-Washing-and-Drying-Line/ to view more product information.