Understanding the Technology Behind “High-Speed Cup Yogurt Filling Machine with CIP Cleaning System”

Yogurt production lines require surgical precision - one equipment failure causes entire batches to spoil. This makes choosing intelligent filling systems critical for modern dairies.

Cup yogurt filling and sealing machines combine portion control accuracy with contamination-free packaging, achieving 99.9% operational reliability. These systems use programmable logic controllers to automate cup feeding, filling volume adjustment, foil sealing, and batch coding processes.

For food engineers seeking to optimize their dairy operations, understanding this technology's working principles separates temporary fixes from long-term solutions. Let's dissect these machines layer by layer.

1.Introduction to Cup Yogurt Filling and Sealing Machines

Cup yogurt filling and sealing machines are used to fill cups with yogurt and then seal them. This helps to keep the yogurt fresh and prevent it from spoiling. Traditional manual filling exposes products to airborne contaminants. Automated systems eliminate human contact while delivering military-grade consistency.These machines integrate three core functions: precise volumetric filling, sterile environment maintenance, and instant heat sealing. They've become indispensable in modern dairies, reducing product giveaway by 3-5% compared to manual methods.

The Machine's Industrial Impact

| Feature | Manual Process | Automated System |

| Output Capacity | 500 cups/hour | 15,000 cups/hour |

| Filling Accuracy | ±8% variance | ±0.5% variance |

| Contamination Risk | High | ISO Class 5 cleanroom standard |

| Labor Required | 6 workers | 1 supervisor |

Our Turkish client reported 83% reduced waste after implementing this technology. The programmable servo motors allow instant recipe changes - from Greek yogurt's thick texture to drinking yogurt's fluid consistency.

2.What are Key Components and Their Functions?

A filling machine's reliability depends on its component synergy. Like Swiss watch mechanics, every part serves multiple precision functions.The three pillars are: 1) Rotary piston fillers for viscous products. 2) Nitrogen flushing systems for shelf-life extension. 3) Induction sealing heads ensuring airtight closure.

Engineering Breakdown

- Filling Mechanism

- Sealing Process

- 12μm aluminum barrier (oxygen protection)

- 45gsm paper base (print surface)

- EVA coating (heat activation)

Sealing heads apply 160°C for 0.8 seconds - enough to bond layers without damaging probiotics.

3.How to work?

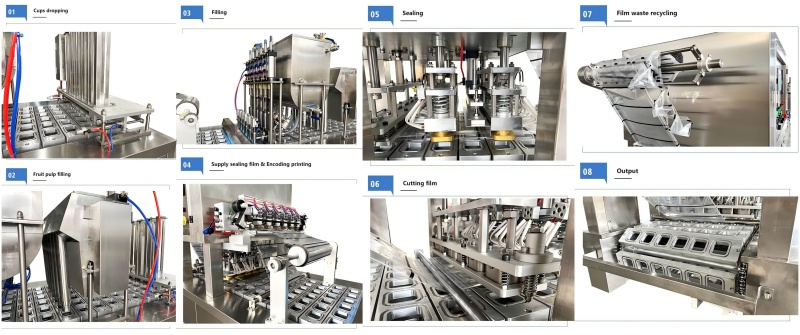

Optimized workflows separate leading dairies from competitors. Our Mexican client reduced changeover time from 45 to 7 minutes using Quick-Change tooling.The 7-stage process: Automatic cups dropping ➔ filling ➔ nitrogen filling ➔ sealing film placement ➔ sealing ➔ batch coding ➔ Output.

System Integration

| Equipment | Data Exchange |

| Cup Molders | Real-time cup dimension feedback |

| Pasteurizers | Temperature synchronization |

| Palletizers | Production speed matching |

4.What are Advantages and Innovations?

Legacy machines waste 200L yogurt daily through dribbling. Today's systems recover 99.3% of product through anti-drip nozzles.Three breakthrough innovations: 1) AI-powered vision inspection rejecting 0.02mm sealing defects 2) Self-cleaning CIP systems reducing downtime 3) New sealing technology reduce energy consumption by 30%.

Technical Evolution Timeline

| Year | Innovation | Impact |

| 2015 | Servo-driven fillers | ±0.25ml accuracy |

| 2018 | RFID tooling recognition | 82% faster changeovers |

| 2021 | Predictive maintenance AI | 95% fewer breakdowns |

| 2023 | Quantum sensors | Real-time viscosity compensation |

Brazilian manufacturer achieved 350% ROI within 14 months using these advancements.

Conclusion

Modern cup filling technology transforms yogurt production through surgical precision, smart integration, and continuous innovation. The future taste of dairy depends on these engineering marvels. Our customizable cup sealing machines are designed for high-speed production, ensuring energy-efficient operations and complies with international food safety standards.Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: https://www.hnunmachinery.com/Automatic-Cups-Filling-and-Sealing-Machine/More video information see view: cups-filling-and-foil-sealing-machine cups-filling-and-sealing-machine coffee-capsule-filling-and-sealing-machine;Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to the cups filling and sealing machine that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.What is the cup filling machine?

2.How to Choose the Perfect Jelly Filling and Sealing Machine?

3.How did jelly get into your mouth?

4.What are the common faults of jelly filling and sealing machine?

5.How much does a jelly filling production line cost?

6.What is a cup yogurt filling and sealing machine?

7.How much is the cup yogurt filling and sealing machine?