Picture this: 96,000 cartons of milk filled hourly with near-zero contamination risk. This is the power of modern aseptic carton filling technology – a marvel of hygienic engineering keeping global food supplies safe.

An aseptic carton milk filler sterilizes packaging, fills sterilized liquid products in sterile environments, and seals containers without human contact. This prevents microbial growth for 6-12 months unrefrigerated, making it ideal for international dairy exports.

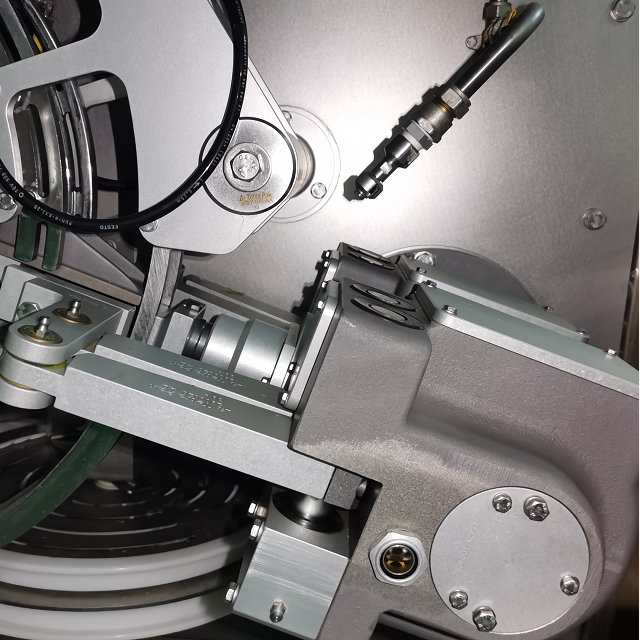

Let's dissect the engineering behind this shelf-stable packaging solution – from sterilization protocols to precision robotic components.

1. What Makes Aseptic Carton Machines Unique?

Traditional filling risks bacterial contamination during packaging. Aseptic systems eliminate this by creating sterile zones for every process step.Aseptic carton fillers achieve commercial sterility (log 6 reduction of microorganisms)through hydrogen peroxide vapor baths and ultra-high temperature (UHT) processing. These dual sterilization barriers allow ambient storage without preservatives.

From almond milk in California to yogurt drinks in Germany – same machine, different products. These machines handle liquids from 100ml to 1L, including milk, juices, soups, and plant-based drinks. Over 80% of EU dairy brands use them for extended shelf life and transport efficiency.

Dive deeper:

Key Innovation: Separation of Sterile Zones

Modern systems divide operations into contamination-controlled chambers:

| Zone | Sterility Level | Key Processes |

| Packaging Material | Log 5 | H2O2 spray + heat drying |

| Product Flow | Log 6 | UHT 140°C/2-4 seconds |

| Closure System | Log 4 | Infrared pre-sterilization |

This triple protection meets FDA 21 CFR 113 guidelines for low-acid canned foods.

2. How Do Filling Systems Achieve 99.95% Efficiency?

A single inefficient seal can waste 200L of product in high-capacity lines. Automated systems prevent this using servo-driven precision.The core workflow combines four synchronized stages: sterilization (0.3 seconds per carton), vertical form-fill-seal (2 cartons/second), volumetric filling (±0.5% accuracy), and hermetic ultrasonic sealing.

Dive deeper:

The Coding Edge: Laser Marking Technology

Integrated coders imprint:

- Batch numbers (16-digit alphanumeric)

- Expiry dates (MM/DD/YYYY + QR code)

- Manufacturing codes (ISO 8601 format)

Our latest X-Series lasers achieve 600 dpi resolution on wax-coated surfaces – crucial for export markets requiring traceability compliance (EU Regulation 178/2002).

3. Why Are Servo-Motor Systems Game Changers?

Conventional fillers waste 9% materials during speed changes. Servo technology reduces this to 1.2% through direct-drive motion control.Digital servo motors adjust fill volumes in 0.01-second intervals, enabling instant switches between 100ml-1L cartons without stopping production.

Ultrasonic Seal Integrity Verification

Advanced models include real-time monitoring:

| Parameter | Measurement Method | Tolerance |

| Seal Thickness | Ultrasonic echo | ±0.08mm |

| Bond Strength | Frequency analysis | 23-27N/15mm |

| Leak Rate | Pressure decay | <0.05 mL/min |

This data feeds into PLCs that auto-reject defective units – crucial for HACCP certification.

4. What ROI Can Exporters Expect?

Operators report 18-month ROI through three key metrics: energy savings, line speed, and export compliance.Our UN-600 model reduces steam consumption by 40% via heat recovery systems, while achieving 28% faster changeovers than industry averages.

Dive deeper:

Your competitors cut packaging costs by 41%. Will you?

Our machines reduce material waste by 22% through precision folding. They switch bottle sizes in 15 minutes and meet Walmart’s packaging specs.

Comparison Table of Advantages

| Traditional equipment | Our equipment |

| 4-hour cleaning | 45-minute CIP automatic cleaning |

| ±5% filling error | ±0.8% error |

| Fixed size | 5 different sizes can be switched quickly |

Conclusion

From hydrogen peroxide sterilization to self-diagnosing PLCs, aseptic fillers combine microbiological safety with smart automation – essential for modern dairy exporters.Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: https://www.hnunmachinery.com/Automatic-juice-filling-machine/Aseptic-Carton-filling-machine.html;More video information see view:https://www.hnunmachinery.com/video/200ml-aseptic-carton-filling-machine.html ; Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to aseptic carton filling production that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.What is the aseptic filling machine?

2.How to ensure the quality and safety of aseptic carton filling products?

3.Aseptic carton filling common problems and solutions.