Table of Contents

· 1. Price Range

· 2. Main Factors Affecting the Price of Straw Sticking Machines

· 3. How to Select the Appropriate Straw Sticking Machine

· 4. Comparison of Different Types of Straw Sticking Machines

Are you choosing a straw sticking machine that fits your milk or beverage packaging? However, there are numerous types of straw sticking machines on the market with huge price differences, making it difficult for people to make a decision at the moment. This hesitation not only affects production efficiency, but may also cause companies to miss market opportunities. So, as a dairy and beverage processing and packaging enterprise, are you worried about the price and choice of straw applicator?

Don't worry. This article will provide you with a detailed answer to the question "How much does a straw sticking machine cost?" and help you understand the factors that influence the price, so that you can make a wise purchasing decision.

Generally speaking, the price range of a straw sticking machine is quite wide, ranging from tens of thousands to hundreds of thousands or even millions of dollars depending on the type and configuration of the equipment. For example, some small straw sticking machines may be priced as low as tens of thousands of dollars, while high-speed fully automatic large straw sticking machines may be priced as high as tens of thousands of dollars or even higher. The specific price of the straw sticking machine needs to be determined based on your production needs and budget.

Price Range

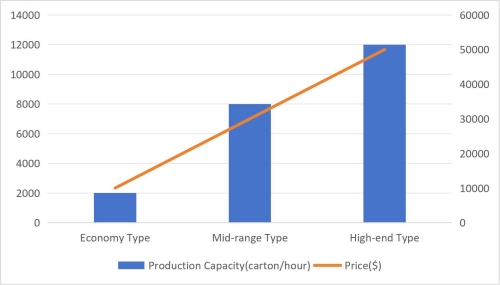

The price of straw sticking machines varies depending on equipment type, production capacity, and technical configuration, typically covering a wide range from economical to high-end models. For basic straw sticking needs, some simple small straw sticking machines or semi-automatic equipment are relatively inexpensive. For example, some basic straw sticking machines on the market may be priced between 10000 to 20000 US dollars, which is suitable for enterprises with small production or limited budgets. For straw sticking production lines that require high speed and automation, prices have significantly increased. Due to the integration of advanced control systems and high-speed operating mechanisms, the price of fully automatic straw sticking machines is usually over 30000 US dollars, and high-end models can even reach 50000 US dollars or higher. In addition, some special purpose or high-precision labeling machines may be much more expensive than those used in the general food industry due to their higher technical complexity.In general, the price range of straw sticking machines can be roughly divided into several grades: economy type (about 10000~20000 US dollars), mid-range type (about 30000~50000 US dollars), and high-end type (over 50000 US dollars, or even higher). Of course, these price ranges are for reference only, and the specific prices will depend on the actual quotes provided by the suppliers.

Main Factors Affecting the Price of Straw Sticking Machines

The price of a straw sticking machine is influenced by various factors, and understanding these factors can help you make trade-offs and choices when purchasing.Firstly, the type of equipment and degree of automation are important factors determining the price. Generally speaking, manual or semi-automatic straw sticking machines have relatively simple structures and lower technical requirements, so their prices are relatively affordable; The fully automatic straw sticking machine integrates complex systems such as mechanical, electrical, control, and pneumatic systems, and can operate continuously at high speeds. Its research and manufacturing costs are higher, and naturally its price is also more expensive. For example, a high-speed fully automatic straw sticking machine, which can achieve functions such as continuous straw sticking, automatic feeding, and automatic removal of defective products, has much higher technical content and price than a semi-automatic model that requires manual cup placement.

Secondly, production capacity and operating speed have a significant impact on prices. The production capacity of a straw sticking machine is usually measured by the number of straw sticking per hour, and the higher the production capacity, the higher the equipment price. Because high production capacity requires machines to use higher specification components in terms of structural strength, power system, control system, etc., to ensure long-term stable operation. For example, a straw sticking machine that can stick 8000-10000 cups per hour is often more expensive than a model that can only stick 2000-3000 cups per hour. This is because the former is more complex in design and materials, and can meet the needs of larger scale production. For example, some straw sticking machines use high-end technologies such as servo motors and precision transmission mechanisms to achieve ultra-high speeds, which will increase equipment costs.

Thirdly, the number of functions and configurations is also a key factor affecting the price. The basic function of a straw sticking machine is to stick straws, but there are significant differences in additional functions among different models. Some high-end straw sticking machines have multiple functions, such as simultaneously sticking straws of different shapes, adapting to various packaging specifications, and having online detection and quality rejection functions. These additional functional modules, such as multi-channel sticking heads, visual inspection systems, automatic adjustment devices, etc., will increase the complexity and cost of the equipment, which will be reflected in the price. On the contrary, if your production process is relatively simple and does not require fancy features, choosing to configure a basic straw sticking machine can save expenses. In addition, the degree of customization of the equipment will also affect the price. If the supplier needs to customize the design based on your special product (such as developing specialized fixtures for containers with special shapes), this usually involves additional research and manufacturing costs, which may lead to an increase in the quotation.

In addition, brand and quality are also factors that cannot be ignored. In the field of packaging machinery, well-known brands or manufacturers with good reputations often have higher prices, which includes brand premiums and trust costs. Internationally renowned brands such as Tetra Pak often have equipment prices much higher than other brands, which is related to their long-term accumulated quality reputation and global service system. Although China's excellent manufacturers of straw sticking machines are more competitive in terms of price, their brand influence may be relatively weak. Therefore, when choosing a straw sticking machine, it is necessary to find a balance between brand awareness and price. If you value affordability more, Chinese made straw sticking machines provide a cost-effective option; But if you prefer world-class quality and global service, you may need to pay a higher price.

Finally, after-sales service and technical support are also factors that affect the total cost. Some suppliers include comprehensive services such as installation, debugging, training, and warranty period in their quotations, while others may only provide basic warranty and require payment for additional services. Comprehensive after-sales service means timely support and spare parts supply when encountering problems during equipment use, which actually reduces downtime risks and long-term maintenance costs. Therefore, when evaluating prices, the supplier's after-sales support capabilities and service costs should also be considered. Some manufacturers offer promises such as one-year warranty and lifetime maintenance, which can save you a lot of trouble and costs in the long run.

How to Select the Appropriate Straw Sticking Machine

In the face of the wide variety of straw sticking machine products on the market, choosing the one that best suits your enterprise's needs is of utmost importance.Firstly, you need to clarify your own production needs. Evaluate your production scale and future growth plans, and determine the production capacity requirements for the straw sticking machine. For example, how many cartons of milk do you plan to produce per hour? Can the maximum speed of the straw sticking machine meet the current and future demand? If your production volume is large, then a high-speed fully automatic straw applicator is necessary; On the contrary, if the output is small or in the initial stage, an economical straw sticking machine may be more cost-effective. Clear requirements can avoid blindly pursuing high-end products and waste, as well as prevent production constraints due to insufficient equipment capacity.

Secondly, product characteristics and packaging forms should be considered. The packaging forms of different dairy products vary, including cup packaging, carton packaging, stand-up pouches, and other types. You need to choose a straw sticking machine that can adapt to your current main packaging form. For example, if your product is mainly packaged in standard brick shapes, you should choose a straw sticking machine specifically designed for brick shapes; If it is a round cup, a round cup sticking machine is required; If it is a stand-up pouch, a stand-up pouch sticking machine is required. Some straw sticking machines claim to be universal, but in actual use, their adaptability to specific packaging may not be as good as specialized models. Therefore, understanding the packaging size and shape of your product, and selecting the corresponding matching straw sticking machine, can avoid problems such as inability to use the equipment normally or low efficiency after purchase.

Thirdly, evaluate the performance and reliability of the equipment. Before procurement, try to obtain the technical parameters and performance indicators of the straw sticking machine as much as possible, such as accuracy, qualification rate, failure rate, etc. These data can help you determine whether the device is stable and reliable. Generally speaking, products from large manufacturers have undergone more market validation and are more guaranteed in terms of reliability and stability. You can request the supplier to provide usage cases of the equipment at other customers' locations, or refer to third-party evaluations. If conditions permit, visiting the supplier's production factory or equipment demonstration in person to observe the operation of the equipment is also a good way to judge its performance. Ensure that the selected straw sticking machine can operate stably for a long time and meet your strict quality requirements.

In addition, pay attention to the usability and maintenance costs of the equipment. A good straw sticking machine should not only meet performance standards, but also be easy to operate and maintain. Assessing whether the operating interface of the device is intuitive and easy to learn, and whether professional programming knowledge is required, will affect the speed of employee acquisition and training costs. In terms of maintenance, understand the brand and lifespan of key components of the equipment such as motors, controllers, glue machines, etc. Therefore, when choosing a straw sticking machine, do not only consider the one-time purchase cost, but also take into account its long-term operation and maintenance costs.

Finally, consider the comprehensive strength and reputation of the supplier. The straw sticking machine is a highly specialized equipment, and the supplier's qualifications and service level directly affect your user experience. Priority should be given to manufacturers with rich experience and complete qualifications in the field of food packaging machinery. You can request to view the supplier's quality system certification (such as ISO certification), past customer feedback, etc. A reliable supplier not only provides equipment, but also offers support in installation, debugging, personnel training, and subsequent upgrades. Good communication and after-sales service are the guarantee for your long-term production. Therefore, before making a decision, it is advisable to compare the solutions and quotations of different suppliers and choose a partner with strong technical strength and good service reputation.

Comparison of Different Types of Straw Sticking Machines

In order to gain a more intuitive understanding of the differences between straw sticking machines, the following will compare and analyze several common models of straw sticking machines. These models have their own characteristics in terms of speed, functionality, and applicability, which you can refer to based on your own needs.

1.Economical straw sticking machine: This type of straw sticking machine usually has a simple structure. Its characteristics are low price, low operational threshold, and suitable for small-scale production or enterprises with limited budgets. In terms of production capacity, it can generally process dozens of items per minute, far lower than fully automatic models. For example, the production capacity of some basic straw sticking machines is about 2000-4000 cartons per hour. Due to the need for manual intervention, its level of automation is relatively low, making it suitable for situations with low output or pursuit of low cost. The advantage is that the initial investment is small and maintenance is relatively simple; The disadvantage is high labor costs, limited efficiency, and difficulty in meeting the needs of high-speed production lines.

2. Mid-range fully automatic straw sticking machine: The mid-range straw sticking machine is a fully automatic model that can achieve automatic feeding, labeling, and discharging without manual intervention. This type of equipment usually uses PLC control and servo drive, with a fast operating speed. It can generally process 5000-8000 cartons per hour, and some models can even process more than 10000 cartons per hour. The mid-range model falls between the economical and high-end models in terms of functionality and price, and is currently the most widely used type of straw sticking machine in the market. They can meet the routine straw sticking needs of most dairy and beverage companies. The cost-effectiveness of mid-range straw sticking machines is outstanding, ensuring high production capacity and automation level, and the price is relatively more affordable compared to high-end equipment. For medium-sized dairy factories or beverage enterprises with a certain scale, mid-range fully automatic straw sticking machines are an ideal choice.

3. High end high-speed straw sticking machine: High end straw sticking machines represent the top level of the industry. This type of device has the characteristics of ultra-high speed and high intelligence. For example, some high-speed straw sticking machines can stick 12000 or even more containers per hour, which can meet the needs of ultra large dairy production lines. High end machines use advanced servo control, visual positioning, high-precision labeling heads, etc. in technology to ensure high labeling accuracy and stability even at high speeds. In addition, high-end models often have comprehensive functions and can support multiple packaging forms and complex processes (such as synchronous labeling, online quality inspection, etc.), with strong adaptability. Of course, its price is also the most expensive. For large dairy enterprises that pursue ultimate efficiency and have a huge production scale, high-end straw sticking machines can bring significant efficiency improvement and quality assurance, but the investment return cycle is relatively long. When making decisions, it is necessary to balance production demand and funding budget.

4.Specific purpose straw sticking machine: In addition to being classified by speed and automation level, there are also some straw sticking machines designed for specific packaging forms or special purposes. For example, the stand-up pouch straw sticking machine is used for sticking straws to stand-up pouches, which are usually equipped with special clamping mechanisms to adapt to the straws of soft bags; The circular cup sticking machine focuses on sticking straws to circular cup-shaped containers, optimizing the design for the curvature of the cup wall. In addition, there are spoon sticking machines used for sticking spoons on dairy packaging. These specific purpose straw sticking machines have their own emphasis on structure and function, and are suitable for the packaging needs of specific products. If your product has a special packaging form, you may choose the corresponding specialized model, which can often achieve better sticking effect and efficiency.

From the above comparison, it can be seen that there are significant differences in speed, functionality, and application scenarios among different models of straw sticking machines. In practical selection, it is recommended that you make targeted comparisons and screenings based on your own product characteristics, production targets, and budget range. For example, if your production is small and your budget is limited, you can consider an economical option; If pursuing efficiency and automation, mid-range fully automated machines are the choice of most enterprises; For large-scale production lines, only high-end high-speed machines can meet the demand. At the same time, don't forget to assess the supplier's technical support and equipment reliability to ensure that the selected straw sticking machine truly becomes a support for your production line.

Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: Drink-Straw-Sticking-Machine More video information see view: Straw Sticking Machine for Cylindrical Containers, Automatic positioning straw sticking machine, How to stick a straw to a beverage carton? Straw sticking machine with sticking straw on top, Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to the straw sticking machine that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.The straw sticking machine you’re looking for!

2.How does the straw sticking machine work?

3.Precautions for operating the straw sticking machine!

4.What issues should you pay attention to when choosing a straw sticking machine?

5.What is the secret to the longevity of straw sticking machines?

6.Common faults and solutions of straw sticking machine.

7.How long is the maintenance cycle of the Straw sticking machine?

8.What should we do if the straw of the straw applicator is not firmly sticked?