If you’re in the jelly, pudding, or dessert business, you know that packaging is just as important as the product itself. A high-quality jelly filling and sealing machine can make or break your production efficiency, product consistency, and profitability. But with so many options on the market, how do you choose the right one for your needs?

In this article, we’ll walk you through the key factors to consider when selecting a jelly filling and sealing machine, ensuring you make an informed decision that aligns with your production goals and budget.

1. Understand Your Production Needs

Before diving into specifications, ask yourself:-What’s your daily or hourly production volume?

- Small-scale producers may only need a semi-automatic machine (500–1,000 cups/hour).

- Large factories require fully automatic machines (2,000–10,000 cups/hour).

-What’s the size and shape of your cups?

Machines are designed for specific cup sizes (e.g., 50ml, 100ml, 150ml) and shapes (round, square, oval). Ensure the machine you choose can handle your packaging format.

-What’s the viscosity of your product?

Jelly textures vary widely—some are thick and chunky, while others are smooth and liquid. Choose a machine with the right filling mechanism (e.g., piston filler for thick jelly, pump filler for liquid jelly).

2. Prioritize Precision and Consistency

A top-tier jelly filling and sealing machine should deliver:-Accurate filling volumes (e.g.,±1% tolerance) to minimize product waste and ensure uniformity.

-Secure sealing to prevent leaks and extend shelf life. Look for machines with adjustable sealing pressure and temperature controls.

3. Check for Hygiene and Compliance

Food safety is non-negotiable. Ensure the machine:- Is made from food-grade materials like 304 or 316 stainless steel.

- Is a CIP system equipped for easy cleaning.

- Meets international standards like FDA, CE, or EHEDG—especially if you’re exporting to regions like the EU or North America.

4. Evaluate Machine Flexibility

Can the machine adapt to future needs? Look for:-Quick-changeover systems to switch between cup sizes or product types.

-Multi-layered filling capabilities if you plan to produce layered jelly desserts.

-Compatibility with eco-friendly packaging (e.g., biodegradable cups or lids) to meet growing consumer demand for sustainability.

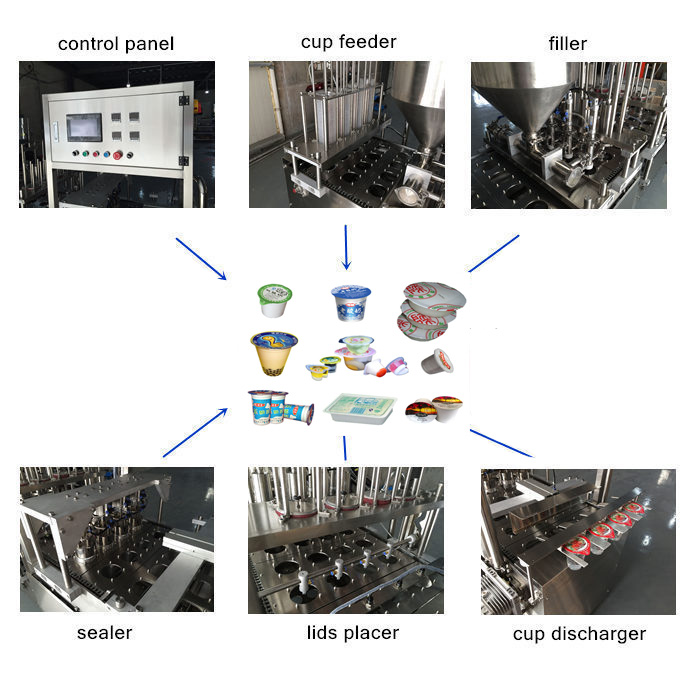

5. Consider Automation Levels

Automation can significantly boost efficiency. Decide between:-Semi-automatic machines: Lower upfront cost, but require more manual labor.

-Fully automatic machines: Higher initial investment, but faster output and reduced labor costs.

Advanced models may also include features like:

-Automatic cup feeding and stacking

-Vision inspection systems to detect defects

-Real-time monitoring via IoT-enabled platforms

6. Don’t Overlook After-Sales Support

A reliable supplier should offer:-On-site installation and training

-Comprehensive warranty and spare parts availability

-24/7 technical support to minimize downtime

7. Compare Costs and ROI

While it’s tempting to go for the cheapest option, consider the total cost of ownership:-Energy efficiency: Machines with lower power consumption save money in the long run.

-Durability: High-quality components reduce maintenance and replacement costs.

-Scalability: Investing in a slightly more advanced machine now can save you from upgrading sooner than necessary.

8. Test Before You Buy

If possible, request alive demonstration or trial run to see the machine in action. This allows you to:- Verify its performance with your specific product and packaging.

- Assess ease of operation and cleaning.

- Identify any potential issues before making a commitment.

Why Choose Union Machinery for Your Jelly Filling and Sealing Needs?

At Union Machinery, we specialize in providing customized, high-performance filling and sealing solutions for jelly and dessert producers worldwide. Our machines are:✅ Built to Last: Made from premium materials for maximum durability.

✅ Globally Compliant: Certified to meet international food safety standards.

✅ Backed by Expertise: Over 11 years of experience and dedicated customer support.

Ready to Upgrade Your Production Line?

Contact us today for a free consultation or to request a product demo. Let us help you find the perfect jelly filling and sealing machine for your business!Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: https://www.hnunmachinery.com/Automatic-Cups-Filling-and-Sealing-Machine/More video information see view: cups-filling-and-foil-sealing-machine cups-filling-and-sealing-machine coffee-capsule-filling-and-sealing-machine;Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to the cups filling and sealing machine that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.What is the cup filling machine?

2.How did jelly get into your mouth?

3.What are the common faults of jelly filling and sealing machine?

4.How much does a jelly filling production line cost?

5.What is a cup yogurt filling and sealing machine?

6.How much is the cup yogurt filling and sealing machine?