Formula production lines stalled due to incompatible machinery? Spoilage claims from improper sealing? These nightmares haunt unprepared manufacturers. Let’s prevent them.

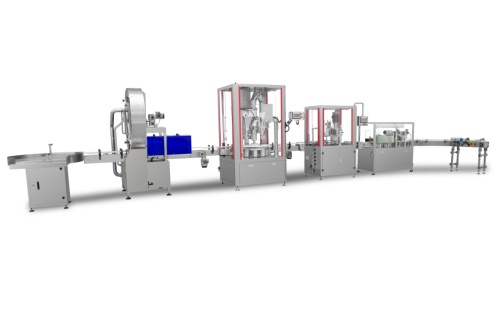

To select infant formula packaging equipment for global markets, match machine specifications to powder characteristics (granule size/moisture), production volumes, material safety standards, automation needs, and ROI calculations. Customizable solutions prove vital for varied international compliance requirements.

The stakes escalate when sealing perishable nutrients for infants worldwide. Let me break down six critical decision factors through 11 years of equipment customization experience.

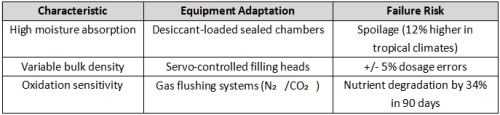

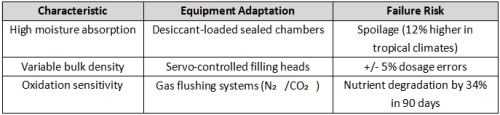

The milk powder particles vary in size? The strong hygroscopicity causes clumping? These problems may reduce your packaging efficiency by more than 30%. If the equipment does not match the product's characteristics, it may either affect the appearance or, in severe cases, lead to nutrient loss or microbial contamination.

Fine powders (<200 microns) require auger fillers with anti-static coatings and nitrogen-flushed chambers to prevent clumping. Coarse granules (>500 microns) work with gravity feeders but need vibration-compensated scales.

Solution:

l Wet-process milk powder: The particles are fine and the moisture content is high. It is necessary to select packaging materials with strong moisture-proof properties (such as aluminum film composite bags) and nitrogen-filled packaging equipment with good sealing performance to prevent moisture absorption and clumping.

l Dry-process milk powder: The particles are coarser and prone to dust. It is necessary to be equipped with high-precision weighing systems and dust recovery devices to ensure uniform packaging and compliance with workshop hygiene standards.

l Special formulas (such as A2 protein, prebiotics): To avoid the destruction of active ingredients by high temperatures or mechanical stress, it is necessary to choose low-temperature filling or flexible conveying systems.

Critical Design Elements Table

Insufficient equipment capacity? Can't the hourly processing capacity keep up with the growth of orders? If small and medium-sized enterprises blindly purchase high-speed equipment, they may waste 50% of their initial investment; However, large enterprises choosing low-speed equipment will miss market opportunities.

Calculate required speeds using: (Annual production target) ÷ (Operating days × 20 hours × 60). Add 25% buffer for maintenance/upscaling. Modular designs allow phased expansions.

l Small/Medium Scale (20-60 bags/min): Recommend modular devices that support flexible expansion and save 40% energy compared to competitors.

l Large Scale (120-300 bags/min): Choose the fully automatic production line, which integrates functions of weighing, filling, sealing and inspection. Integrated lines with parallel filling channels reduce downtime by 73%.

l Seasonal demand fluctuations: Prioritize equipment with adjustable capacity, achieving flexible production through variable frequency motors or modular design.

Does the packaging material conflict with the ingredients of the milk powder? Did the metal detector miss detecting foreign objects? A single case of material compatibility failure could lead to a million-dollar recall cost.

Demand FDA/EU-compliant contact surfaces: 316L stainless steel (Ra<0.8μm polish) for chambers, medical-grade silicones for seals. Multi-layer film handlers should process PET/AL/PE composites.

Material Compliance Checklist:

✅ ISO 22000 /ISO 9001 certification

✅ 3.1mm radius edges (prevents biofilm)

✅ CIP/SIP capabilities

✅ <0.5% residual cleaning agents (EC 1935/2004)[1]

When Australian regulators banned BPA-lined pouches in 2023, 37% of conventional machines became obsolete overnight. Future-proof materials matter.

Prioritize:

l Basic Automation: Utilizing PLC control systems to achieve automatic weighing and filling, with an error control within ±0.5%.

l Advanced Intelligent Functions: Such as AI visual inspection (identifying powder leakage, poor sealing) and IoT remote monitoring, reducing the fault response time by 70%.

l Human-Machine Collaboration Design: For instance, the operation interface supports multi-language switching, reducing training costs.

Cost-Benefit Analysis (5-year span):

Cost-Benefit Analysis (5-year span):

A Turkish plant reduced quality inspection staff from 12 to 3 after installing our vision inspection systems. Smart automation pays within 8 months.

Essential customizations:

- Sizes: 50g-2kg capacity switching under 8 minutes

- Printing: 8-color CIJ printers with variable data

- Shapes: From standard cans to hexagonal milk cans.

Customization Cost Guide:

When a Nigerian client demanded hexagonal milk powder cans, standard machines failed. Our custom team delivered in 5 weeks.

Double the maintenance cost of low-priced equipment? High investment equipment idle rate of 40%? Wrong cost decisions may lead to a 60% decrease in overall ROI.

ROI formula: (Annual savings × 5) - Initial cost. Target <3-year payback. Consider:

- Energy use: Compare kW/h per 1000 packs

- Maintenance: Our machines need 60% fewer spare parts

- Downtime: 98.5% uptime guaranteed

Conclusion

Selecting milk powder packaging equipment demands technical precision and market foresight. With 50+ country certifications and 100+ customization cases, our solutions ensure you pack quality into every gram. Let’s engineer your global success story.

Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: Milk Powder Filling Production Line;Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to milk powder packaging line that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.How to Build an Efficient Canned Milk Powder Packaging Line?

To select infant formula packaging equipment for global markets, match machine specifications to powder characteristics (granule size/moisture), production volumes, material safety standards, automation needs, and ROI calculations. Customizable solutions prove vital for varied international compliance requirements.

The stakes escalate when sealing perishable nutrients for infants worldwide. Let me break down six critical decision factors through 11 years of equipment customization experience.

1. How Should Product Characteristics Dictate Equipment Selection?

The milk powder particles vary in size? The strong hygroscopicity causes clumping? These problems may reduce your packaging efficiency by more than 30%. If the equipment does not match the product's characteristics, it may either affect the appearance or, in severe cases, lead to nutrient loss or microbial contamination.

Fine powders (<200 microns) require auger fillers with anti-static coatings and nitrogen-flushed chambers to prevent clumping. Coarse granules (>500 microns) work with gravity feeders but need vibration-compensated scales.

Solution:

l Wet-process milk powder: The particles are fine and the moisture content is high. It is necessary to select packaging materials with strong moisture-proof properties (such as aluminum film composite bags) and nitrogen-filled packaging equipment with good sealing performance to prevent moisture absorption and clumping.

l Dry-process milk powder: The particles are coarser and prone to dust. It is necessary to be equipped with high-precision weighing systems and dust recovery devices to ensure uniform packaging and compliance with workshop hygiene standards.

l Special formulas (such as A2 protein, prebiotics): To avoid the destruction of active ingredients by high temperatures or mechanical stress, it is necessary to choose low-temperature filling or flexible conveying systems.

Critical Design Elements Table

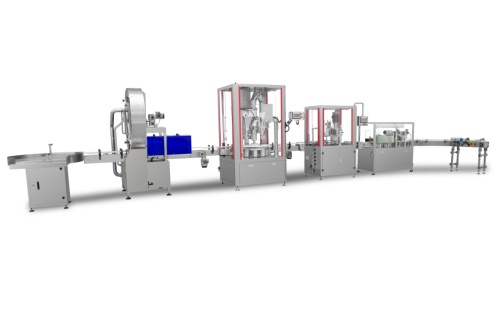

2. Production Speed & Capacity: How to Match Your Business Scale?

Insufficient equipment capacity? Can't the hourly processing capacity keep up with the growth of orders? If small and medium-sized enterprises blindly purchase high-speed equipment, they may waste 50% of their initial investment; However, large enterprises choosing low-speed equipment will miss market opportunities.

Calculate required speeds using: (Annual production target) ÷ (Operating days × 20 hours × 60). Add 25% buffer for maintenance/upscaling. Modular designs allow phased expansions.

l Small/Medium Scale (20-60 bags/min): Recommend modular devices that support flexible expansion and save 40% energy compared to competitors.

l Large Scale (120-300 bags/min): Choose the fully automatic production line, which integrates functions of weighing, filling, sealing and inspection. Integrated lines with parallel filling channels reduce downtime by 73%.

l Seasonal demand fluctuations: Prioritize equipment with adjustable capacity, achieving flexible production through variable frequency motors or modular design.

3. Material Compatibility: How to Ensure Safety and Flexibility?

Does the packaging material conflict with the ingredients of the milk powder? Did the metal detector miss detecting foreign objects? A single case of material compatibility failure could lead to a million-dollar recall cost.

Demand FDA/EU-compliant contact surfaces: 316L stainless steel (Ra<0.8μm polish) for chambers, medical-grade silicones for seals. Multi-layer film handlers should process PET/AL/PE composites.

Material Compliance Checklist:

✅ ISO 22000 /ISO 9001 certification

✅ 3.1mm radius edges (prevents biofilm)

✅ CIP/SIP capabilities

✅ <0.5% residual cleaning agents (EC 1935/2004)[1]

When Australian regulators banned BPA-lined pouches in 2023, 37% of conventional machines became obsolete overnight. Future-proof materials matter.

4. Automation Level: How to Reduce Labor Costs and Errors?

Manual operation leads to filling errors exceeding ±2%? Night shift labor costs increase by 30%? Enterprises with insufficient automation may spend an additional $150,000 per year. 。Prioritize:

l Basic Automation: Utilizing PLC control systems to achieve automatic weighing and filling, with an error control within ±0.5%.

l Advanced Intelligent Functions: Such as AI visual inspection (identifying powder leakage, poor sealing) and IoT remote monitoring, reducing the fault response time by 70%.

l Human-Machine Collaboration Design: For instance, the operation interface supports multi-language switching, reducing training costs.

| Automation Level | Labor Savings | Error Reduction | Payback Period |

| Basic | 30% | 50% | 18 months |

| Advanced | 50% | 87% | 12 months |

| Smart Factory | 75% | 98% | 10 months |

A Turkish plant reduced quality inspection staff from 12 to 3 after installing our vision inspection systems. Smart automation pays within 8 months.

5. Customization Options: How to Adapt to Unique Packaging Needs

Can't adapt to special can types? Customized requirements resulting in a delivery delay of 3 months? Standardized equipment is difficult to meet the niche needs of emerging markets.Essential customizations:

- Sizes: 50g-2kg capacity switching under 8 minutes

- Printing: 8-color CIJ printers with variable data

- Shapes: From standard cans to hexagonal milk cans.

Customization Cost Guide:

| Modification | Lead Time | Cost Premium |

| Dimensional change | 2-4 weeks | 15-28% |

| New material trial | 2-3 weeks | 22% |

| Complete line revamp | 8-12 weeks | 35-50% |

When a Nigerian client demanded hexagonal milk powder cans, standard machines failed. Our custom team delivered in 5 weeks.

6. Initial Investment vs. Long-Term ROI: How to Balance?

Double the maintenance cost of low-priced equipment? High investment equipment idle rate of 40%? Wrong cost decisions may lead to a 60% decrease in overall ROI.

ROI formula: (Annual savings × 5) - Initial cost. Target <3-year payback. Consider:

- Energy use: Compare kW/h per 1000 packs

- Maintenance: Our machines need 60% fewer spare parts

- Downtime: 98.5% uptime guaranteed

Conclusion

Selecting milk powder packaging equipment demands technical precision and market foresight. With 50+ country certifications and 100+ customization cases, our solutions ensure you pack quality into every gram. Let’s engineer your global success story.

Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: Milk Powder Filling Production Line;Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to milk powder packaging line that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.How to Build an Efficient Canned Milk Powder Packaging Line?