Roll film packaging machines and premade bag packaging machines are widely used in the packaging industry, each with its own characteristics and suitable for different production needs. So, how to choose between a roll film packaging machine and a premade pouch packaging machine? Based on 10 years of production practice experience, UNION Machinery compares the two in detail from the following dimensions for your reference.

Contents

1. What are the differences in packing materials?

2. What are the differences between structure and working principle?

3. Which is more flexible?

4. Which is faster and more efficient?

5. Which has better packing quality?

6. Which equipment is more expensive?

7.Conclusion

1.What are the differences in packing materials?

Packaging material form:- Roll film packaging machine: Using rolled packaging film as packaging material. This type of roll film is usually made of various materials, such as plastic film (PE, PP, PET, etc.), composite film, etc. The cost of roll film is relatively low, and the packaging size and shape can be flexibly adjusted according to actual packaging needs. It can achieve various packaging forms, such as three side sealing, four side sealing, pillow packaging, etc. But the roll film needs to be formed and sealed on-site on the packaging machine.

- Premade bag packaging machine: Premade bags are used for packaging. There are various types of prefabricated bags, including three side sealed bags, four side sealed bags, stand-up bags, zipper bags, etc. The premade pouches have completed the molding and most of the processing steps in the manufacturing factory, and the quality and shape are relatively stable. However, the cost of prefabricated bags is relatively high, and once the bag type is selected, the packaging form is basically fixed. When changing the packaging form, different types of prefabricated bags need to be replaced.

Material cost:

- Roll film packing machine: Roll film is usually supplied in larger sized rolls, with relatively low procurement costs. And because the packaging size can be flexibly adjusted according to actual needs, it can reduce material waste to a certain extent.

- Premade bag packing machine: Prefabricated bags have undergone processing such as molding, so the cost is relatively high. And if it is necessary to replace bags of different types or sizes, it often requires re procurement, with significant cost fluctuations.

2. What are the differences between structure and working principle?

Working Principle:- Rolling film packaging machine: During operation, the rolled film of packaging is released from the rolling film equipment, the film is made into a cylinder by a shaper, and is surrounded around the product to be packaged. Then the side of the film is sealed by the longitudinal sealing device, and the product is moved with the film to the transverse sealing device for horizontal sealing and cutting to complete a packaging unit. This packaging machine can flexibly adjust the length and width of the packaging according to the size and packaging requirements of the product.

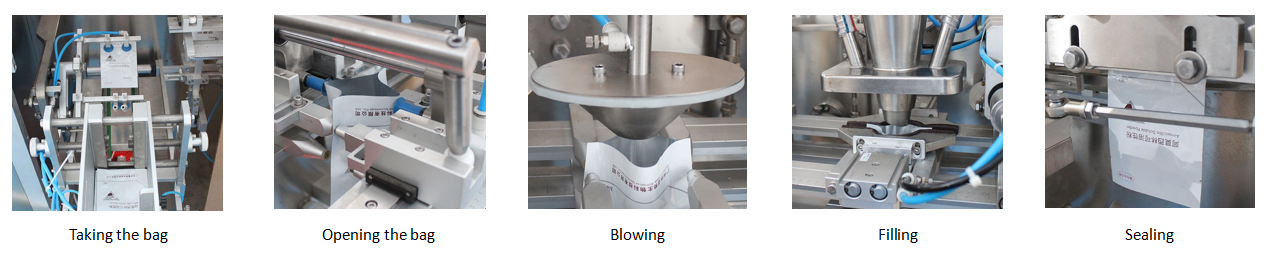

- Prefabricated bag packaging machine: It transports premade bags (such as three sided sealed bags, four sided sealed bags, stand-up bags, etc.) to the packaging station, opens the bag opening through the opening mechanism, fills the product into the bag through the filling mechanism, and finally completes the sealing operation through the sealing mechanism.

Structural complexity:

- Roll film packaging machine: The structure is relatively complex, including multiple parts such as unwinding film device, forming machine, longitudinal sealing device, transverse sealing device, cutting device, and control system. Accurate coordination is required between various parts to ensure the smooth progress of the packaging process.

- Premade pouch packaging machine: The structure is relatively simple, mainly composed of bag feeding mechanism, bag opening mechanism, filling mechanism, and sealing mechanism. However, these institutions require a high level of coordination in their actions.

3. Which is more flexible?

Product adaptability:- Roll film packaging machine: It has high flexibility and can adapt to product packaging of different shapes and sizes by adjusting parameters such as the molding machine, edge banding, and cutting device. It has high flexibility. Especially suitable for packaging testing of new products and production needs of small batches and multiple varieties. For example, in the food industry, film packaging machines can easily switch packaging forms for products such as cookies and candies of different specifications.

- Premade pouch packaging machine: The packaging form depends on the type of prefabricated bag and is relatively fixed. Once a certain prefabricated bag is selected, the packaging form is basically determined. However, when packaging products with specific shapes or special requirements, it can utilize the advantages of prefabricated bags to provide better packaging effects, such as self standing bags suitable for displaying liquid or powder products. But if it is necessary to change the packaging form, it often requires the replacement of different types of prefabricated bags, which is relatively less flexible.

Diversity of packaging forms:

- Roll film packaging machine: Capable of implementing various packaging forms, such as pillow packaging, three side sealing, four side sealing, self-supporting bags, suction nozzle bags, zipper bags, shaped bags, etc. By adjusting the equipment, packaging bags of different shapes and structures can be created to meet diverse market demands.

- Premade pouch packaging machine: The packaging form is mainly limited to the type of premade bag used. Although there are also various types of prefabricated bags to choose from, it is not as innovative and varied in packaging form as the roll film packaging machine.

4. Which is faster and more efficient?

Packing speed:- Roll film packaging machine: On high-speed production lines, the packaging speed of roll film packaging machines is relatively fast. Due to its continuous feeding and packaging process, as long as the film supply and equipment operation are stable, high production efficiency can be maintained. Some advanced film packaging machines can complete dozens or even hundreds of packaging operations per minute.

- Premade bag packaging machine: Due to the relatively complex processes of conveying and opening prefabricated bags, and the intermittent nature of the entire packaging process, its packaging speed is relatively slow.

Conversion efficiency:

- Roll film packaging machine: When it is necessary to change the packaging specifications or products, the roll film packaging machine needs to adjust the parameters of the equipment, and may also need to replace or debug the molding machine and other components. This process usually takes some time and will affect the overall production efficiency to a certain extent.

- Premade bag packaging machine: When changing products or packaging specifications, if the size of the prefabricated bag is appropriate, there is generally no need to make significant adjustments to the equipment. Therefore, in production scenarios with small batches, multiple varieties, and frequent product changes, the overall efficiency of the prefabricated bag packaging machine may not be lower than that of the roll film packaging machine.

5. Which has better packing quality?

Appearance quality:- Roll film packaging machine: During the packaging process, due to the continuous molding and sealing of the film, the sealing quality is usually good, which can ensure the sealing and stability of the packaging. But if the equipment is not properly debugged or the film quality is poor, problems such as weak sealing and wrinkles may occur. In addition, when packaging products with irregular shapes, the roll film packaging machine may require more skills and experience to ensure the flatness and beauty of the packaging appearance.

- Premade bag packaging machine: The prefabricated pouch has passed strict quality inspection in the production process, and its quality and shape are more stable. Therefore, the premade bag packaging machine can better ensure the appearance quality of the package when packaging, and the shape of the bag is more regular.

Sealing quality:

- Roll film packaging machine: By adjusting the parameters of the longitudinal and transverse sealing devices reasonably, the roll film packaging machine can achieve good sealing effect. However, if the equipment is not properly debugged or there are issues with the film quality, there may be situations such as weak sealing and air leakage.

- Premade bag packaging machine: Prefabricated bags have undergone strict sealing quality testing during the production process. As long as the sealing mechanism of the packaging machine is working properly, the quality of the sealing can generally be guaranteed. However, if there is a malfunction in the bag opening or sealing mechanism, it may also lead to problems such as incomplete opening or loose sealing of the bag opening.

6. Which equipment is more expensive?

Equipment cost:- Roll film packaging machine: Due to the relatively complex structure and high technical content of the equipment, the price of the equipment is usually quite expensive. Moreover, the quality requirements for packaging film are high for the roll film packaging machine. Improper use or film quality problems may cause equipment failure and increase maintenance costs.

- Premade bag packaging machine: The equipment structure is relatively simple and the price is relatively low. However, the cost of prefabricated bags is usually higher than that of rolled film, and over time, the cost of packaging materials will become an important expense factor.

Maintenance difficulty and cost:

- Roll film packaging machine: Maintenance is difficult and requires professional technicians to perform regular maintenance and upkeep. The multiple moving parts and complex control systems of the equipment require frequent inspection and debugging, and the cost of replacing components is relatively high.

- Premade bag packaging machine: Relatively easy to maintain, mainly focusing on mechanisms such as bag feeding, opening, and sealing. However, if these institutions malfunction, they also need to be repaired in a timely manner to ensure the normal operation of the packaging machine.

7.Conclusion

In summary, the roll film packaging machine is suitable for large-scale, high-efficiency production scenarios that require high flexibility in packaging forms; Premade bag packer are more suitable for production situations with high requirements for packaging appearance, diverse product varieties but small batch sizes, and little demand for changes in packaging forms. When choosing, enterprises should comprehensively consider factors such as their own production scale, product characteristics, packaging requirements, and cost budget to make the most suitable decision.Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: https://www.hnunmachinery.com/Automatic-Packing-Machine/Automatic-Horizontal-Packaging-Machine/;Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to the Horizontal packaging machine that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.What is the horizontal bag making packer?

2.What is a premade bag horizontal packaging machine?

3.What are the common faults of the roll film horizontal packaging machine?

4.How to choose an excellent roll film horizontal packaging machine?

5.How to choose between horizontal packaging machine and vertical packaging machine?

6.What factors should be considered when purchasing a roll film stand up pouch packaging machine?