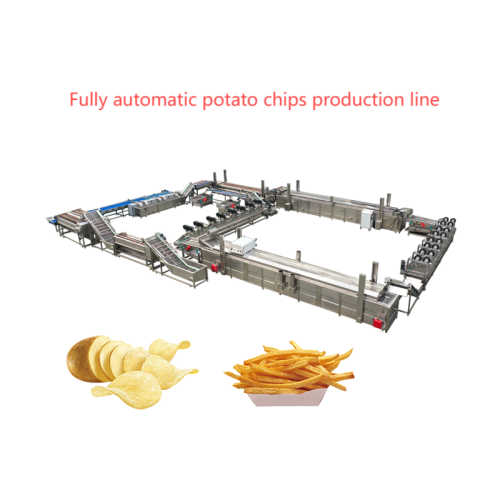

In modern society, fried potato chips are a popular snack food, and the industrial production process behind their production is full of a sense of technology and innovation. This article will take you to a deeper understanding of the main equipment and functions of the fried potato chip production line, revealing the story behind this delicious dish.

Process flow:

Cleaning Peeling - Picking - slicing - cleaning - blanching - Air drying - frying - Deoiling - seasoning - packaging

1. Cleaning and Peeling

Function description: The first step of the production line is to thoroughly clean and peel fresh potatoes to remove sediment and impurities on the skin. The equipment used in this step has powerful brushing ability and precise peeling technology, ensuring the cleanliness and quality of the raw materials.

Main equipments:

- Cleaning machine: It uses high-pressure water flow flushing or rotating brushes to effectively remove soil and other impurities from the surface of potatoes.

- Peeling machine: The peeling machine with diamond sand or a brush type cleaning peeling machine is used to remove the potato skin, ensuring smooth and clean subsequent slicing.

- Picking line: Used to inspect and clean peeled potatoes, remove defective or incompletely peeled materials.

2. Slicer

Function description: Next, the potatoes will be fed into a slicer to be evenly sliced, which is a key step in determining the final shape and taste of the potato chips. Modern slicers can precisely control the slice thickness, ensuring that each potato chip is evenly cooked during the frying process.

Main equipments:

- Slicer: This machine uses sharp blades to slice cleaned and peeled potatoes into thin slices. The thickness can be adjusted according to different product requirements, generally between 0.1mm and 2mm, to ensure uniform expansion and crispness formation of potato chips during frying.

- Cleaning machine: Clean the starch on the surface of potato chips.

3. Blanching and Draining

Function description: Briefly pre cook potato chips to soften the starch structure and perform color protection and sterilization. Then remove excess moisture through a vibrating screen to prepare for frying. Pre cooking and draining can improve frying efficiency while reducing oil absorption.

Main equipments:

- Blanching machine: Inhibits enzyme activity through high-temperature water blanching for color protection and sterilization.

- Vibration dewatering screen: It removes moisture from the surface of materials through a vibrating screen and is also used to evenly transport materials to the next stage.

- Air drying machine: Remove excess moisture from the material in a short period of time through high-pressure air, and air dry the surface moisture of the blanched material.

4. Deep frying

Function description: The frying machine is the core of the potato chip production line, where potato chips are instantly dehydrated in high-temperature cooking oil, forming a signature crispy texture. The frying machine is equipped with a temperature control system to ensure constant oil temperature, as well as a circulating filtration system to keep the oil clean and extend its service life.

Main equipments:

- Frying machine: Fry potato chips or fries until golden brown, crispy and delicious, and extend shelf life.

- Air drying machine: In order to lock in the aroma and maintain crispness, fried potato chips need to be degreased and quickly cooled down to lower the temperature of the chips to suitable storage conditions, while also reducing the risk of steam condensation during packaging.

5. Seasoning

Function description: Use high-speed stirring to evenly coat each potato chip with seasoning, adding rich flavor.

Main equipment:

- Seasoning machine: automatically seasoning by rotating the drum.

6. Weighing and packaging

Function description: Finally, the seasoned potato chips are sent to the weighing system, accurately measured according to different packaging specifications, and then packed with nitrogen through the automatic packaging machine to isolate oxygen, delay the oxidation process, and maintain the freshness and crispness of potato chips.

Main equipment:

- Weighing and packaging machine: The fully automatic packaging machine packages products according to packaging requirements for easy storage and transportation.

7. Quality inspection and packing

Function Description: Potato chips also need to go through strict quality inspection during the production process, and eliminate the products that do not meet the standards. After that, the qualified chips will be neatly stacked on pallets, packed using automatic palletizer, and ready to be sent to local markets.

Main equipments:

- Color sorter: The potato chips that do not meet the product requirements are removed.

- Foreign matter detection machine: Detect whether there is foreign matter in potato chips, and remove unqualified products.

- Packing machine: Put the packaged products into cartons and palletise them neatly.

Every step of the fried potato chip production line embodies the exquisite design and technological progress of modern food industry. From raw materials to finished products, every step strives for excellence, just for the delicious and unforgettable experience. Through the synergistic effect of the above equipment and process flow, we are able to enjoy the classic snack that is fragrant and crispy - fried potato chips, satisfying people's infinite thirst for food.

Through the above steps, you can gradually improve the accuracy of the feeding mechanism of the pillow packaging machine, ultimately achieving high-quality and high-efficiency packaging operations. Remember, fine tuning often requires multiple attempts, patience and attentiveness are the key to success.

Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: https://www.hnunmachinery.com/Production-Line/Fried-Potato-Chips-Production-Line.html; Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to potato chips production line that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.What are the methods and precautions for selecting a potato chips production line?

2.What is the maintenance cost of the potato chip production line?

3.How long does it take to replace key components in the potato chip production line?

4.What is the raw material loss rate in potato chip production?

5.What are the common causes of wastage in potato chip production?

6.How to do daily inspection of potato chips production line?

7.Maintenance skills for potato chip production line.