Agitation: Traditional methods might involve manual cleaning or separate washing and sanitizing steps, which are slow, labor-intensive, and risk re-contamination.

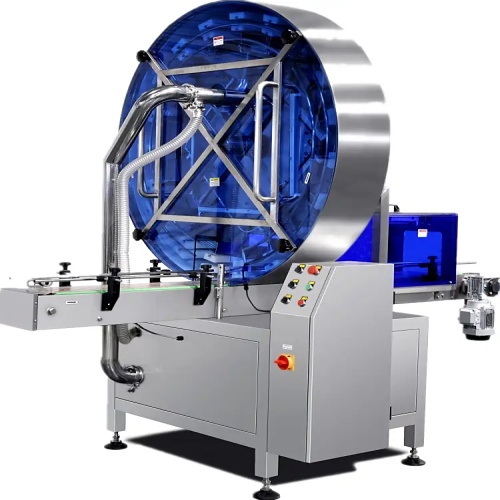

A magnetic-free empty can cleaning and disinfection machine is a specialized equipment designed to automatically clean and sterilize empty cans (such as food or beverage cans) without using magnets. It typically combines mechanical cleaning (like air or water jets) with a disinfection method (often ultraviolet light or other non-chemical means) to remove debris and kill pathogens in one continuous operation. This ensures each can is free of contaminants and microbiologically safe before filling, improving product quality and safety while boosting production efficiency.

How Does a Magnetic-Free Empty Can Cleaning and Disinfection Machine Work?

You might be wondering, how exactly does a machine clean and disinfect cans without any magnets?Magnetic-free can cleaner use a clever combination of cleaning and sterilization techniques. These machines work by first removing physical contaminants from the cans and then applying a disinfecting treatment. Typically, empty cans are fed into the machine where an air or water jet (or brush) cleans out any dust or debris. Next, the cans are exposed to a germicidal agent – commonly UV-C light – which penetrates microbial cells and destroys their DNA/RNA, rendering them harmless. This combined cleaning and disinfection is done in a single pass, ensuring each can is sanitized before it moves to the filling station. The result is a highly efficient, one-step process that guarantees clean, sterile cans for your products.

What Are the Key Functions and Benefits of Magnetic-Free Cleaning and Disinfection Machines?

You want to ensure your product’s packaging is contaminant-free and safe, but you might be concerned about the effectiveness and efficiency of new cleaning technology. Using separate cleaning and disinfecting steps can lead to delays, extra labor, or even re-contamination between steps.Magnetic-free can cleaning and disinfection machines are engineered to maximize cleanliness and safety while streamlining your production. By integrating cleaning and sterilization into one unit, they eliminate the need for manual handling or intermediate storage of cans, thus preventing cross-contamination that could occur if cans were moved from a washer to a disinfector separately. Additionally, because they don’t rely on magnets to attract metal particles, they thoroughly remove all types of debris (including non-magnetic dirt or residues) that magnetic systems might miss. The benefits include higher throughput, consistent hygiene quality, and reduced downtime for cleaning the machine itself. In short, these machines keep your cans pristine and your production running smoothly, protecting both your product and your brand reputation.

What Are the Typical Applications and Use Cases for These Machines?

You might be asking, “In which industries or situations would a magnetic-free can cleaner be most useful?”The non-magnetic empty can cleaning and disinfection machine, due to its efficient and chemical-free cleaning and disinfection characteristics, has a wide application prospect in various food processing and packaging fields.

| Industry Type | Application Scenario | Function and Advantages |

| Large and Medium-Sized Food Processing and Packaging Enterprises | Pre-treatment of the empty cans of various canned foods (such as canned fruits, canned meats, canned vegetables, etc.). | Ensure the sterility of the packaging containers, extend the product's shelf life, and comply with strict food safety standards. |

| Beverage Processing Enterprises | Clean and disinfect empty cans of canned beverages (such as carbonated drinks, fruit juice, tea drinks, beer, etc.). | Prevent the impact of microbial contamination on the flavor and quality of beverages, and ensure the safety of consumers' drinking. |

| Dairy Processing and Packaging Enterprises | Pre-treatment of empty cans of products such as canned milk, yogurt, and milk beverages. | Dairy products have extremely high hygiene requirements. Non magnetic cleaning and UV disinfection can effectively prevent bacterial growth and ensure product quality. |

| Fast-moving Consumer Goods Packaging Enterprises | Various canned packaging for fast-moving consumer goods (such as snacks, seasonings, etc.). | Improve the hygiene level of the packaging process, reduce the risk of product recalls, and safeguard the brand reputation. |

| Grain Processing Enterprises | Cleaning of empty cans of canned grains, beans, nuts, etc. | Prevent mold and bacterial contamination, and keep the food products dry and fresh. |

| Fruit Processing Enterprises | Clean and disinfect empty cans of canned fruits, jams, puree, etc. | Ensure that the natural flavor and nutritional components of the fruit products remain unaltered and uncontaminated. |

| Vegetable Processing Enterprises | Pre-treatment of empty cans of canned vegetables, pickles, etc. | Maintain the texture and nutrition of the vegetable products and prevent them from spoiling and deteriorating. |

| Large-scale Farm | Canned agricultural products after primary processing (such as homemade jam, pickled products, etc.). | Provide safe and hygienic packaging solutions for agricultural products to enhance their added value. |

| Large-scale Catering Industry | Canned pre-made dishes from central kitchens or large catering chains. | Ensure the hygiene and safety of pre made dishes and extend their shelf life in the supply chain. |

What Are the Best Practices for Operating a Magnetic-Free Can Cleaning and Disinfection Machine?

You’ve invested in this high-tech cleaning machine – how do you make sure you operate it correctly to get the best results? Improper operation could lead to cans not being fully cleaned or even damage to the machine.

To keep your magnetic-free can cleaner running smoothly and effectively, follow these best practices.

First, train your operators on the machine’s controls and safety features. Make sure they know how to adjust settings (like conveyor speed or UV exposure time) according to the can type and production needs.

Always inspect the machine before starting up: check that the UV lamps are functioning, air nozzles are unclogged, and any filters (if present) are clean.

When running the machine, maintain the recommended throughput – running too many cans too fast might reduce the cleaning/disinfection time per can, compromising results. Conversely, very low throughput might not be efficient.

Monitor the process regularly: watch for any cans that aren’t being properly handled or any unusual noises/errors from the machine. Use the machine’s control system (often a simple interface or PLC) to set the correct parameters; for instance, some systems allow variable speed to match your line speed.

Safety is key: ensure operators are aware not to look directly at the UV lamps or reach into the machine while it’s running (many machines have interlocks that shut off the UV when the door is opened, for safety).

Also, if your machine uses compressed air, make sure the air supply is clean and dry to avoid introducing moisture or oil into the cans.

By following these operational guidelines, you’ll maximize the machine’s performance and ensure every can that comes out is perfectly cleaned and disinfected.

How Should You Maintain and Care for a Magnetic-Free Can Cleaning and Disinfection Machine?

Like any equipment, your can cleaner needs regular maintenance to keep it in top condition. Neglecting maintenance could lead to breakdowns, reduced cleaning efficiency, or even safety hazards (for example, a dirty UV lamp might not disinfect properly).

Maintaining a magnetic-free can cleaning and disinfection machine is straightforward but important. Here are some maintenance tips:

Clean the machine regularly – since it’s cleaning cans, it will accumulate dust and debris over time. Wipe down the interior surfaces and conveyor parts periodically to prevent buildup. If your machine has UV lamps, keep the lamp surfaces clean; dust or residue on a UV lamp can block the germicidal rays, so gently wipe the lamps with a soft, dry cloth (or as per manufacturer’s instructions) to maintain their output.

Replace UV lamps as recommended – UV bulbs lose intensity over time. Typically, after about 8,000–9,000 hours of use (roughly one year of full-time operation), the lamps should be replaced to ensure they still provide effective disinfection. Many manufacturers or operators schedule an annual lamp replacement as part of routine maintenance.

Also, check any filters or air lines – if the machine uses air blowers, the air filters should be cleaned or replaced to ensure a steady, clean air supply.

Inspect the mechanical components (conveyor drive, gears, etc.) for wear and lubricate them as needed.

Keep an eye on the machine’s performance indicators; if you notice a drop in disinfection efficacy (e.g., microbial test failures) or a decrease in cleaning power, it may be time for maintenance or replacement of parts.

Finally, always follow the manufacturer’s maintenance schedule provided in the user manual, which may include daily, weekly, and monthly tasks.

By proactively maintaining your machine, you’ll extend its lifespan and ensure it continues to deliver the high level of cleanliness and safety your production demands.

How Do Magnetic-Free Cleaning Systems Compare to Traditional Magnetic Cleaners?

You might be considering different types of can cleaning systems and wondering how a “magnetic-free” machine stacks up against older magnetic-based systems.

Magnetic-free can cleaning and disinfection machines offer several advantages over traditional magnetic cleaners.

First, they eliminate the limitations of relying on magnetism – magnetic systems can only pick up ferrous (iron-based) materials. Non-magnetic dirt, plastic fragments, or food residues would not be captured by a magnet and could still contaminate a can. In contrast, a magnetic-free system uses physical cleaning (like air or water jets) to blast out all types of debris, ensuring a more thorough removal of contaminants. Additionally, magnetic cleaners sometimes have issues where metal particles get stuck and are not fully released, requiring manual cleaning of the magnet. Magnetic-free systems avoid this problem entirely – there’s no magnet to collect and hold debris, so the risk of leftover particles is greatly reduced.

Another big difference is the built-in disinfection: traditional magnetic cleaners typically only remove physical contaminants, whereas magnetic-free machines include a sterilization step (like UV light) that kills bacteria and viruses on the can surface. This means the output of a magnetic-free system is not just cleaner but also safer from a microbiological standpoint.

Furthermore, by combining cleaning and disinfection in one unit, magnetic-free machines streamline the process and reduce the need for additional equipment (you wouldn’t need a separate UV sterilizer or chemical sanitizer after the magnetic cleaner, for example).

In summary, magnetic-free can cleaning systems provide a more comprehensive cleaning (catching all debris, not just metal), ensure microbial safety through integrated disinfection, and simplify the workflow by doing more in one step. They represent a modern upgrade over older magnetic cleaners, addressing both the physical and biological aspects of can hygiene effectively.

Are There Any Limitations or Considerations Specific to Magnetic-Free Systems?

While magnetic-free can cleaners sound great, are there any drawbacks or special things to consider when using them?

One consideration for magnetic-free systems is that they rely on UV light for disinfection, which requires direct exposure to surfaces and may be less effective if cans are heavily soiled or wet (hence a preliminary cleaning is important). Additionally, UV lamps must be properly maintained and replaced to ensure ongoing disinfection efficacy. Despite these points, magnetic-free machines are designed to handle typical can cleaning scenarios effectively, and their limitations are manageable with proper operation and maintenance.

Conclusion

Investing in a magnetic-free empty can cleaning and disinfection machine can significantly elevate your production line’s hygiene and efficiency. By understanding how these machines work – combining thorough cleaning with integrated UV sterilization – and by implementing the best practices for operation and maintenance, you’ll ensure that every can that reaches your filling station is immaculate and safe. The key functions and benefits, from removing all types of contaminants to preventing recontamination, make this technology a valuable asset for food and beverage manufacturers. Whether you’re in the beverage, dairy, or food canning industry, a magnetic-free can cleaner is designed to meet the rigorous demands of modern production while simplifying your workflow. By following the guidelines outlined in this article, you’ll be well-equipped to leverage this technology effectively, ultimately safeguarding your product quality and consumer trust.

Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: Magnetic Free Empty Can Cleaning And Disinfection Machine、Milk Powder Filling Production Line;Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to magnetic-free can cleaning and disinfection machine that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.What are the common faults of the magnetic-free empty can cleaning and disinfection machine?

2.How to Maintain and Service a Non-Magnetic Empty Can Cleaning and Disinfecting Machine?