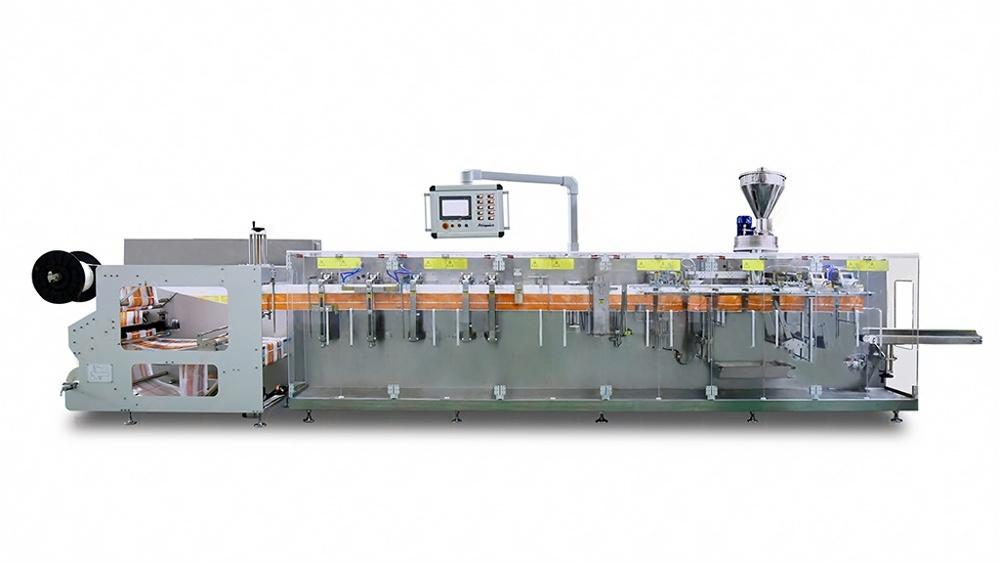

As a precision and efficient automated equipment, the roll film horizontal packaging machine(also know as horizontal bag making packer) may encounter some common problems or malfunctions during long-term operation. Understanding these problems can help diagnose and solve them in a timely manner, and maintain the smooth progress of production. Here are some typical faults that may be encountered and their causes:

1. Poor formed of packaging bags

Reason: It may be due to improper film temperature, mold wear, or insufficient pressure.Solution: Check if the temperature controller is working properly and adjust the temperature of the heating rod; Check if the mold is clean and damaged, and if necessary, clean or replace the mold; Adjust the pressure to ensure sufficient air pressure.

2. The seal is not secure enough

Reason: The temperature at the sealing area is too low, the sealing blade is damaged or not completely closed, the sealing strip is worn or dirty, the pressure is insufficient or uneven.Solution: Adjust the temperature of the heating component to a suitable level, check if the sealing blade is intact, and replace it with a new one if it is damaged to ensure accurate braking of the sealing machine.

3. Slow packaging speed

Reason: Insufficient motor power, control system delay, or mechanical component aging.Solution: Check the motor performance and consider upgrading or replacing the old motor; Optimize control programs to reduce unnecessary waiting time; Regular maintenance, lubrication, and replacement of worn parts.

4. Large packaging deviation

Reason: Unstable feeding system, measurement sensor malfunction, or improper control system parameter settings.Solution: Adjust the feeding mechanism to ensure smooth and continuous operation; Check and calibrate sensor accuracy; Reset control system parameters to make machine operation more coordinated and consistent.

5. Frequent downtime

Reason: Circuit problems, software conflicts, or excessive load.Solution: Check the power line, eliminate the electrical fault; Update or optimize control software to prevent program conflicts; Monitor workloads to avoid overloading.

6. Abnormal equipment noise

Reason: Bearing or gear wear, lack of lubrication, loose fixing screws.Solution: Regularly inspect and replace worn parts, fully lubricate moving parts, and tighten all connections.

7. Film breakage or jamming

Reason: Excessive traction, quality issues with the film, and foreign objects obstructing the guide track.Solution: Reduce traction appropriately, use high-quality film materials, clean or correct the guiding track.

8. Poor packaging appearance

Reason: The cutting blade is dull and the layout is not aligned.Solution: Sharpen or replace the cutter, adjust the layout, and ensure that the pattern is correct and not offset.

For the above problems, regular maintenance, following the manufacturer's guidance, and timely response to alarm information are effective means to prevent failures. In complex cases, it is advisable to contact professional technicians or equipment suppliers for detailed inspection and repair to avoid greater damage caused by misoperation.

Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: https://www.hnunmachinery.com/Automatic-Packing-Machine/Automatic-Horizontal-Packaging-Machine/;Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to the Horizontal packaging machine that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.What is the horizontal bag making packer?

2.What is a premade bag horizontal packaging machine?

3.How to choose an excellent roll film horizontal packaging machine?

4.How to choose between horizontal packaging machine and vertical packaging machine?

5.What factors should be considered when purchasing a roll film stand up pouch packaging machine?

6.How to choose between roll film packaging machine and premade bag packaging machine?