Last article we introduced what is the horizontal bag making and packaging machine, today I will take you to understand what is the premade pouch horizontal packaging machine.

Contents

1. Definition2. Advantages

3. Workflow

4. Scope of application

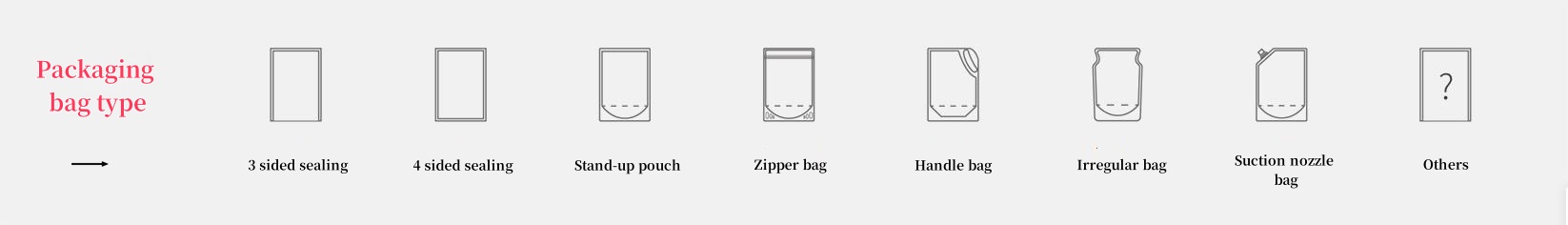

5. Type of packaging bag

6. Types of Packaging Materials

7. Conclusion

1. Definition

Premade bag horizontal packaging machine, also known as bag-given horizontal packaging machine, is an efficient and automated professional packaging equipment, mainly used for filling and sealing pre-made bags. Unlike traditional on-site bag making and packaging machines, prefabricated bag horizontal packaging machine does not require immediate formation of packaging bags on site, but directly use pre-prepared bags for filling and sealing, providing great flexibility and convenience for packaging in certain special situations.This packaging machine is suitable for various materials such as powders, granules, liquids, pastes, etc., widely used in food, medicine, cosmetics and other industries.

2. Advantages

a. Personalized packaging: Premade bags often have unique designs that are suitable for brand customization and enhance visual recognition.b. Avoiding pollution risks: Compared to on-site bagging, it reduces the chance of materials coming into contact with the external environment and is more suitable for packaging sensitive products.

c. Wide adaptability: Due to not being limited to specific packaging materials, it is possible to adapt to packaging bags of different shapes and sizes, such as zipper bags, self-supporting bags, oxygen absorbing bags, etc., by adjusting parameters and changing molds.

d. Flexibility: When changing product specifications, only the bag type needs to be changed, without the need for significant adjustments to equipment settings.

e. Efficient and stable: Automated operations improve packaging speed, reduce error rates, achieve continuous operations, ensure packaging quality and consistency, greatly improve production efficiency, especially suitable for large-scale production line needs.

f. Low maintenance cost: The structure is relatively simple, with fewer vulnerable parts, and manufacturers usually provide professional after-sales service, resulting in relatively low maintenance costs.

3. Workflow

a. Packaging process for Standard premade bag :Prefabricated bag stacking, flipping and taking bags, opening bag, blowing, filling, sealing, finished.

b. Packaging process for Zipper premade bag:

Prefabricated bag stacking, flipping and taking bags, opening zipper, opening bag, blowing, filling, sealing, finished.

c. Packaging process for suction nozzle:

Premade bag stacking, flipping and taking bags, opening bags, blowing, filling, adding nozzles, sealing, finished.

4. Scope of application

It has an extremely wide range of applications and can be used for paper plastic composites, plastic plastic composites, aluminum-plastic composites, PE composites, etc. It has low packaging material loss and uses pre made packaging bags with perfect patterns and good sealing quality, thereby improving product quality; It is an ideal packaging machine for industries such as food, spices, pharmaceuticals, cosmetics, chemicals, agriculture, pet food, etc.5. Type of packaging bag

6. Types of Packaging Materials

By matching different measuring devices according to different materials, can fully automatic packag various products such as granules, powders, blocks, liquids, soft cans, toys, hardware, etc.Granules: biscuits, potato chips, candy, cooked food, coffee beans, tea, dried fruit, peanuts, beans, rice, snacks, tablets, capsules, pet food, fertilizer, headphones, phone cases, hardware accessories, etc.

Liquid: juice, beverage, yogurt, condiment, cooking oil, vinegar, mouthwash, syrup, shampoo, body wash, cosmetics, laundry detergent, lubricating oil, nutrient solution, etc.

Powder: milk powder, seasoning powder, pepper powder, sugar, coffee powder, flour, protein powder, medicine powder, salt, spices, laundry powder, etc.

Mixing materials: tomato sauce, sala sauce, broad bean sauce, chili sauce, jelly, seasoning sauce, moisturizing cream, etc.

7. Conclusion

The premade bag horizontal packer is suitable for enterprises that value personalized packaging and have special packaging needs, such as high-end food, cosmetics, pharmaceutical products, fine chemicals and other industries, providing safe, beautiful and differentiated packaging solutions for products.Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: https://www.hnunmachinery.com/Automatic-Packing-Machine/Automatic-Horizontal-Packaging-Machine/;Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to the Horizontal packaging machine that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.What is the horizontal bag making packer?

2.What are the common faults of the roll film horizontal packaging machine?

3.How to choose an excellent roll film horizontal packaging machine?

4.How to choose between horizontal packaging machine and vertical packaging machine?

5.What factors should be considered when purchasing a roll film stand up pouch packaging machine?

6.How to choose between roll film packaging machine and premade bag packaging machine?