Horizontal packaging machine, also known as horizontal working packing machine, is a modern packaging equipment widely used in packaging production lines of multiple industries such as food, medicine, chemical, and daily consumer goods. Its working principle is to complete the forming, filling, and sealing process of packaging materials through horizontal movement, thereby achieving efficient and high-quality automatic packaging of products.

Horizontal packaging machines are mainly divided into two types: horizontal bag making packaging machines and premade bag horizontal packaging machines. Today, I will take you to understand what is a horizontal bag making packer.

Contents

1. Definition2. Advantages

3. Workflow

4. Scope of application

5. Type of packaging bag

6. Types of Packaging Materials

7. Conclusion

1.Definition

Horizontal bag making packer: That is, a packaging equipment that uses rolled packaging film as raw material to automatically make bags, fill, and seal in a horizontal direction. This type of packaging machine starts from the roll packaging film, and uses a forming device to form the film into a bag shape according to the set width and shape. Then, the product (which can be solid, liquid, powder, granule, sauce, etc.) is automatically filled into the formed bag, and the bag is heated and sealed by a heat sealing device to complete the packaging.This machine is widely used in various industries such as food, medicine, and daily chemical products, especially on production lines that require high-speed and large-scale packaging.

2. Advantages

a. High production efficiency: sustained and stable output of production capacityThe intelligent control system and servo drive technology have achieved high-speed operation without sacrificing packaging quality, shortened the production cycle, and significantly improved production efficiency.

b. Wide applicability: flexible adaptation to multiple materials

Whether it is PE, CPP, BOPP, aluminum foil composite film or other roll films, whether it is powder, particle, liquid or mixed materials, the machine can easily handle them, providing you with diversified packaging choices.

c. Strong compatibility: flexible workstations, compatible with expansion

More workstations are reserved, and packaging workstations can be freely added or reduced according to packaging needs (such as increasing from single head filling to double head filling, etc.), without the need to replace the entire production line.

It can be linked with other production equipment, such as palletizing machines, labeling machines, etc., to build a complete production line and improve the overall automation level.

d.High product quality: closed-loop inspection to ensure product quality

Closed environment packaging, online weighing, bag detection, height detection, coding detection and other tests, can be more accurate real-time monitoring of the efficiency of the whole machine, accurate control of product quality.

e. Easy to operate: Automation makes operation easier

The touch screen interface is simple and intuitive, and the novice can quickly grasp it, greatly reducing the operation threshold, and 1 person can complete the operation, saving labor costs.

Support multi-client and multi-user browsing, real-time display of statistical production data and display of equipment running status.

f. Cost saving: Highly automated to achieve cost reduction and efficiency improvement

Fully servo driven control, precise die-cutting reduces the consumption of film materials. Accurate filling reduces material waste. Save 30% -50% of packaging costs.

3. Workflow

a. Main packaging process for standard flat bag:Placing roll film, forming packaging film, color code inspection, bottom sealing, vertical sealing, cutting, opening bags, filling, sealing, finished.

b. Main packaging process of doypack Pouch:

Placing roll film, bottom punching, forming packaging film, bottom sealing, vertical sealing, color code detection, cutting, bag clamping, bag opening, blowing, filling, sealing, finished.

c. Main packaging process of zipper bag:

Placing zipper, Placing roll film, forming packaging film, color code detection, top seal zipper, bottom seal, vertical seal, cutting, bag clamping, bag opening, filling, sealing, finished.

d. Main packaging process of suction nozzle bag:

Placing roll film, bottom punching, forming packaging film,bottom sealing, vertical sealing, color code detection, cutting, bag clamping, opening, blowing, filling, adding suction nozzle, sealing nozzle, sealing, finished.

e. Main packaging process of irregular bag:

Placing roll film, forming packaging film, color code inspection, bottom sealing, vertical sealing, cutting, opening bags, filling, sealing, finished.

4. Scope of application

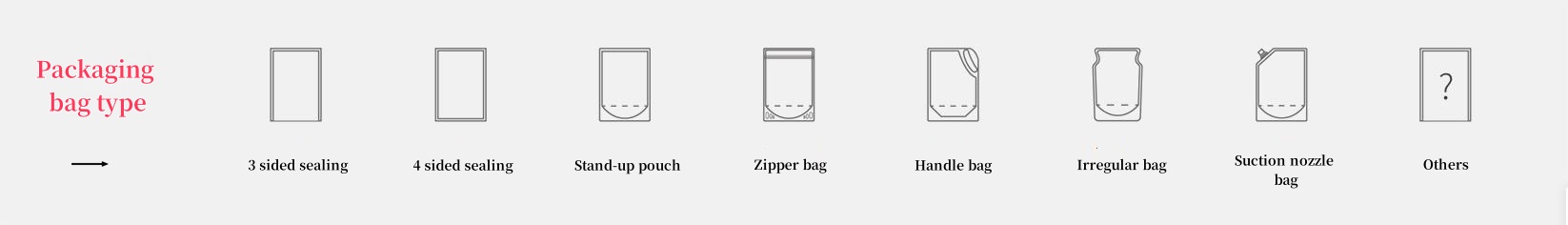

It is the ideal packaging machine for food, fragrance, pharmaceutical, cosmetics, chemical, agriculture, pet food and other industries.5. Type of packaging bag

6. Types of Packaging Materials

Can meet various types of item packaging, such as granules, liquids, powders, and mixed materials.Granules: biscuits, candy, cooked food, coffee beans, tea, dried fruit, peanuts, beans, rice, snacks, tablets, capsules, pet food, fertilizer, headphones, phone cases, hardware accessories, etc.

Liquid: juice, beverage, yogurt, condiment, cooking oil, vinegar, mouthwash, syrup, shampoo, body wash, cosmetics, laundry detergent, lubricating oil, nutrient solution, etc.

Powder: milk powder, seasoning powder, pepper powder, sugar, coffee powder, flour, protein powder, medicine powder, salt, spices, laundry powder, etc.

Mixing materials: tomato sauce, sala sauce, jelly, seasoning sauce, moisturizing cream, etc.

7. Conclusion

Horizontal bag making and packaging machine, with their high efficiency, precision, and versatility, has become an ideal choice for modern manufacturing industries to pursue high-quality, low-cost, and high-efficiency packaging, and have become an indispensable part of the modern packaging industry.Union Machinery has been engaged in food machinery customization services since its establishment in 2014, according to customer needs for you to tailor suitable machinery and equipment, for more product information, please refer to: https://www.hnunmachinery.com/Automatic-Packing-Machine/Automatic-Horizontal-Packaging-Machine/;Our expertise and advantages will bring you more opportunities and development space.

For personalized, industry-tailored advice and to explore state-of-the-art solutions, please don't hesitate to contact us at info@unmachinery.com

The following is other knowledge related to the Horizontal packaging machine that I have summarized based on long-term work experience, for your reference. I hope it will be helpful to you.

1.What is a premade bag horizontal packaging machine?

2.What are the common faults of the roll film horizontal packaging machine?

3.How to choose an excellent roll film horizontal packaging machine?

4.How to choose between horizontal packaging machine and vertical packaging machine?

5.What factors should be considered when purchasing a roll film stand up pouch packaging machine?

6.How to choose between roll film packaging machine and premade bag packaging machine?