Continuous Film Sealing Machine can be made horizontally, vertically or with stand feet. It can seal plastic film in various kinds of materials....Read more

VIDEO

Introduction

This continuous sealing machine is a new model of automatic plastic continuous film sealing machine, which integrates color printing, sealing, continuous transmission of products, with clean and bright pattern on the sealing part, color selectable, instant printing and instant dry, and convenient to change the characters.Features:

1. Strong sealing seam2. this bag sealing machine has no limited to sealing length

3. Rugged Powder Coated All-Metal Construction

4. Create sealing width Max. 14 MM

5. Sealing belts are oriented horizontally to allow for easy access and high throughput

6. Max loading weight of 3 KGS is ideal for most consumer good

7. Sealing speed and temperature of the continuous sealing machinery are adjustable with film thickness to ensure sealing quality

8. Electronic constant temperature mechanism

9. Stepless speed regulating transmission motor

10. Flexible height and wide changed with packet size

11. Can print code date, batch number

Main structure and working principle:

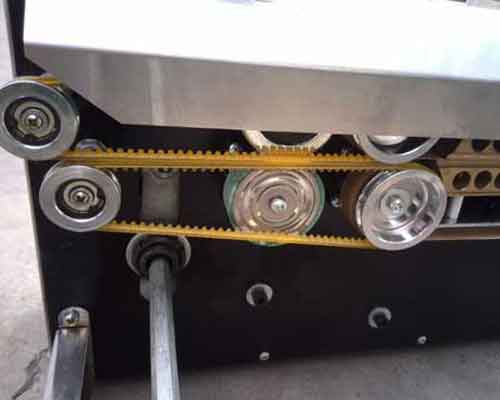

1. This continuous sealer consists of frame, speed reducer, transmission mechanism, heating radiator, seal imprint, conveying equipment, electric and electronic control system components, etc.2. Put through power supply, the agencies began to work. Electric heating element after the electricity heating, make up and down heating blocks is rapidly growing and access control system to adjust to the required temperature; embossing wheel rotation. According to the need to start the cooling cooling system; Conveyor belt turn, and by adjusting speed regulating device to the desired speed.

3.When loaded with goods packaging placed on a conveyer belt, bag sealing part is automatically sent to the two sealing belt running and to the heating area, heating blocks of heat through the sealing belt transmission to the bag sealing parts, thin film by hot melt soft, again through the cooling area, make the film surface temperature appropriate, and then through the knurled wheel (or printing roller wheel, make the sealing parts and plastic film adhesion and suppress the reticular pattern (or print logo), and then by rubber belt and conveyor belt will seal good bags sent clear, complete sealing operation.

Application:

This series continuous bag sealer is suitable for small bags packing and adopts electronic constant temperature control system and speed adjusting transmission mechanism. It can seal plastic films of various materials. such as PE, PP, Aluminum foil. And can be fixed date embossing system.Specification:

| Model | YYD-900 | YYH-900 | YYF-900 |

| voltage | 110/220V 50-60Hz | ||

| Transmission power | 60W | ||

| Sealing heating rate | 300*2 W | ||

| Sealing speed | 0-16m/min & 0.26m/min | ||

| Sealing width | 8-10mm | ||

| Sealing film thickness | 0.02-0.08mm | ||

| Temperature range | 0-300°C adiustable | ||

| Printing type | steel printing | ||

| Machine weight | 25kg | 30kg | 35kg |

| Machine size | 840*380*320mm | 840*380*550mm | 540*550*800mm |