Garlic production line is mainly used for garlic bulb separating, garlic peeling with garlic processing equipment and it can be used for deep processing of the garlic clove. ...Read more

Introduction:

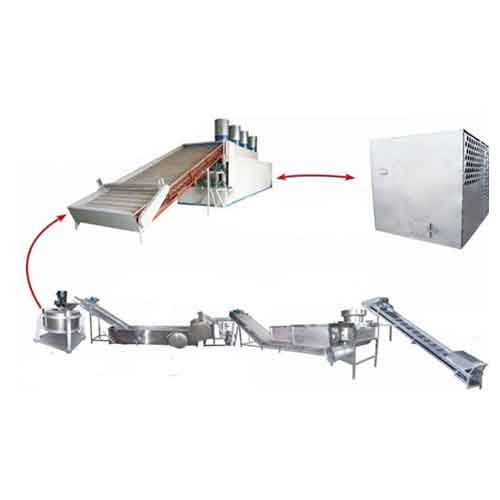

The whole garlic processing line consists of garlic separator, garlic peeling machine, garlic slicer, garlic dicing machine, and garlic dryer. The garlic dryer is the mesh belt dryer, it includes the boiler, the feeding machine, the drying box, and the moisture-removing device, so it is the necessary drying equipment for garlic glove, garlic slice and various vegetables and fruits.

Application:

This garlic production line is mainly used to process garlic from the whole garlic to dry garlic slice.The garlic processing line:

Working theory:

The garlic peeling machine adopts pneumatic theory, and it processes the separated garlic into garlic cloves without any damage. There is no need to put the garlic into water, the garlic peeler can be used in all kinds of garlic.Process flow:

Material-feeding- garlic bulbs separating- peeling- skin rinsing- washing - sterilize- cleaning and gravel removing - slicing- water drain- dryingAdvantages:

1. Automatic digital control, easy to operate, safe and convenient.2. High efficiency, fast processing speed, and labor-saving.

3. High rate of the whole garlic clove, no damage to garlic.

4. Suitable for large batch production in vegetable processing factory, canteen or individual shops.

5. The whole processing line is mainly designed for the processing of the garlic products and the products will be processed thoroughly according to requirements of customers’.

6. Components of the whole production line are made of stainless steel, so it has high quality and has advantages of anti-corrosion

7. The appearance of the machines is beautiful and it can be applied in different kinds of garlic products and it is the ideal choice for customers.

8. The production line is environmental friendly and energy saving.